Vasanth

Dec 10, 2025

Some industries evolve over decades. The semiconductor world evolves in quarters. One year you're scaling production to meet demand for automotive chips; the next you're hit with export bans, new cybersecurity standards, and a dozen fresh disclosures about supply chain vulnerabilities. What makes all of this even messier is that semiconductor compliance—unlike general corporate compliance—isn't just paperwork. It's legal, manufacturing, and national security risks tangled together.

If you're in the thick of it, you already know: the rules rarely come one at a time. The market shifts, regulators respond, and suddenly you’re updating engineering workflows, supply chain documentation, and cybersecurity protocols all at once. At Certivo, we see this every day as we work with compliance-driven teams across fabs, OSATs, design houses, and automotive chip suppliers.

And that’s why the real challenge isn't just compliance—it’s navigating the pace of compliance.

Why Semiconductor Compliance Is Different

In most industries, regulations dictate how products are sold. But in this field, they dictate who can design it, who can make it, which country can receive it, and whose IP touches it along the way.

This is where semiconductor compliance becomes more than checkboxes—these become strategic decisions. The need to demonstrate Semiconductor compliance isn’t just coming from governments; it's also from OEMs, auditors, and hyperscalers demanding transparency. And by the time you achieve it, the specs may already be shifting.

That’s just the nature of this ecosystem.

Similarly, Semiconductor regulatory compliance forces companies to balance engineering realities—fabrication cycles, test architecture, EDA workflows—with policy demands. Many teams approach Semiconductor regulatory compliance reactively, fixing issues after audits, but forward-looking companies operationalize it through continuous monitoring rather than annual panic.

It's an ongoing negotiation, not a finish line.

The Global Maze of Semiconductor Regulations

There is no unified rulebook—just overlapping frameworks influenced by national security laws, IP controls, and safety standards. Companies operating globally face global semiconductor regulations that differ not only by region but also by export class and end-use case. When supply chains cross oceans, compliance with Global semiconductor regulations becomes a shared responsibility across integrators, distributors, and foundries. And because new laws are emerging every quarter, maintaining visibility into Global semiconductor regulations requires active intelligence, not static documentation.

From export controls to data protection to ESG mandates, everything is interlocked.

Just a snapshot:

Semiconductor export controls tied to national security

Cross-border semiconductor compliance in multi-country fabrication chains

Export control compliance semiconductor requirements for restricted chipsets

Licensing requirements for semiconductor products classified as dual-use tech

Trade regulations in the semiconductor industry are tied to geopolitical relations.

Even minor reclassification of chip architecture can change permissible shipping routes overnight.

SEMICON Standards: Engineering Meets Compliance

The SEMI standards aren't just bureaucracy—they define how fabs prove equipment integrity, traceability, and process security.

Both SEMI E187 compliance and SEMI E188 compliance have become crucial for the secure handling of sensitive chip manufacturing data. As fabs move toward digital automation and remote tooling, SEMI E187 becomes a core part of data-protection and risk-control frameworks—not just a certification checkbox.

Meanwhile, SEMI E188 governs the authentication of secure equipment configurations. Vendors increasingly require SEMI E188 compliance before approving integration into advanced lithography and high-automation workflows. As threat vectors rise, meeting E188 requirements is becoming a competitive differentiator—far beyond routine paperwork.

Safety & Automotive Standards: Chips That Cannot Fail

In automotive, medical, aerospace, and defense applications, safety standards aren't optional. Take ISO 26262 semiconductor certification. A chip used in ADAS systems needs full functional-safety lifecycle traceability. Many engineering leaders assume that ISO 26262 semiconductor certification applies only at the OEM level, but semiconductor design houses are increasingly responsible for safety audits. And achieving ISO 26262 semiconductor certification requires documenting not just hardware safety but tool qualification, software stacks, and hazard analysis.

Now add quality systems: fabs aiming for defense and healthcare supply chains need ISO 9001 semiconductor quality management to formalize processes. As sustainability reporting grows, ISO 9001 semiconductor quality management is becoming an upstream requirement for prime contractors. And when traceability is part of ESG, ISO 9001 semiconductor quality management becomes proof of ethical production, not just efficiency.

Cybersecurity raises another layer. Modern fabs exchange massive tool-level data; without controls, it's a breach waiting to happen. That's where ISO 27001 information security semiconductor frameworks come into play. With rising attempts at IP theft, ISO 27001 information security standards are becoming the norm in semiconductor design environments, especially those interacting with hyperscalers. And even small firms are implementing ISO 27001 information security standards to meet data-security clauses in supplier agreements.

Data Protection & Cybersecurity Requirements

Compliance doesn't stop at chip safety—now it touches personal data. With rising digital integration, fabs handling user or device-linked data are increasingly subject to:

GDPR semiconductor compliance

CCPA semiconductor data protection

Data privacy regulations for semiconductor

Cybersecurity compliance of semiconductors

Semiconductor data security

Plus the technical side:

Malware scanning through semiconductor equipment

Vulnerability scanning of semiconductors

Compliance monitoring of semiconductors

Security now extends from fab OT networks to cloud-hosted digital twins.

Supply Chain Transparency: Now Required, Not Requested

A single chip passes through dozens of suppliers. One non-compliant step affects the entire chain.

Semiconductor manufacturing compliance

Semiconductor supply chain compliance

Supply chain regulatory compliance

Quality management systems semiconductor

This is where digital compliance platforms matter. Paper-based tracking just isn't enough when regulations change mid-production, and certifications expire unnoticed. Teams now adopt compliance management software and semiconductor tools—not because it's convenient, but because audits require proof on the spot. Modern chains must show provenance, traceability, environmental reporting, export permission, and defect-level transparency.

That’s a lot to ask from a spreadsheet.

Export Controls: The New Battleground

The industry has shifted from performance competition to geopolitical competition. Controlled process nodes, lithography tools, and advanced AI accelerators fall under:

Semiconductor export controls

Cross-border semiconductor compliance

Export control compliance for semiconductor

Licensing requirements for semiconductor

And we haven’t even touched IP yet.

Intellectual Property & Legal Risk

Chips contain millions of proprietary logic blocks. As collaboration expands, protecting design IP is just as important as achieving certifications.

Terms that now shape risk posture:

Intellectual property protection for semiconductor

Environmental compliance semiconductor

Global compliance framework for the semiconductor industry

Navigating semiconductor regulatory challenges

This isn’t theoretical—it's survival.

Where Companies Go Wrong (And How to Avoid It)

Most failures we see don't come from lack of effort—they come from lack of continuity.

Common traps:

Mistake | Result |

|---|---|

Treating compliance as periodic | Non-compliance gaps during updates |

Using spreadsheets | Missing audit trails |

No unified risk ownership | Conflicting department standards |

Decentralized supplier vetting | Process contamination upstream |

What works instead:

Compliance technology-based solutions

Continuous review instead of annual audits

Real-time workflow visibility

Shared accountability across engineering, IT, and supply chain

This turns compliance from reactive enforcement to proactive resilience.

How Certivo Helps

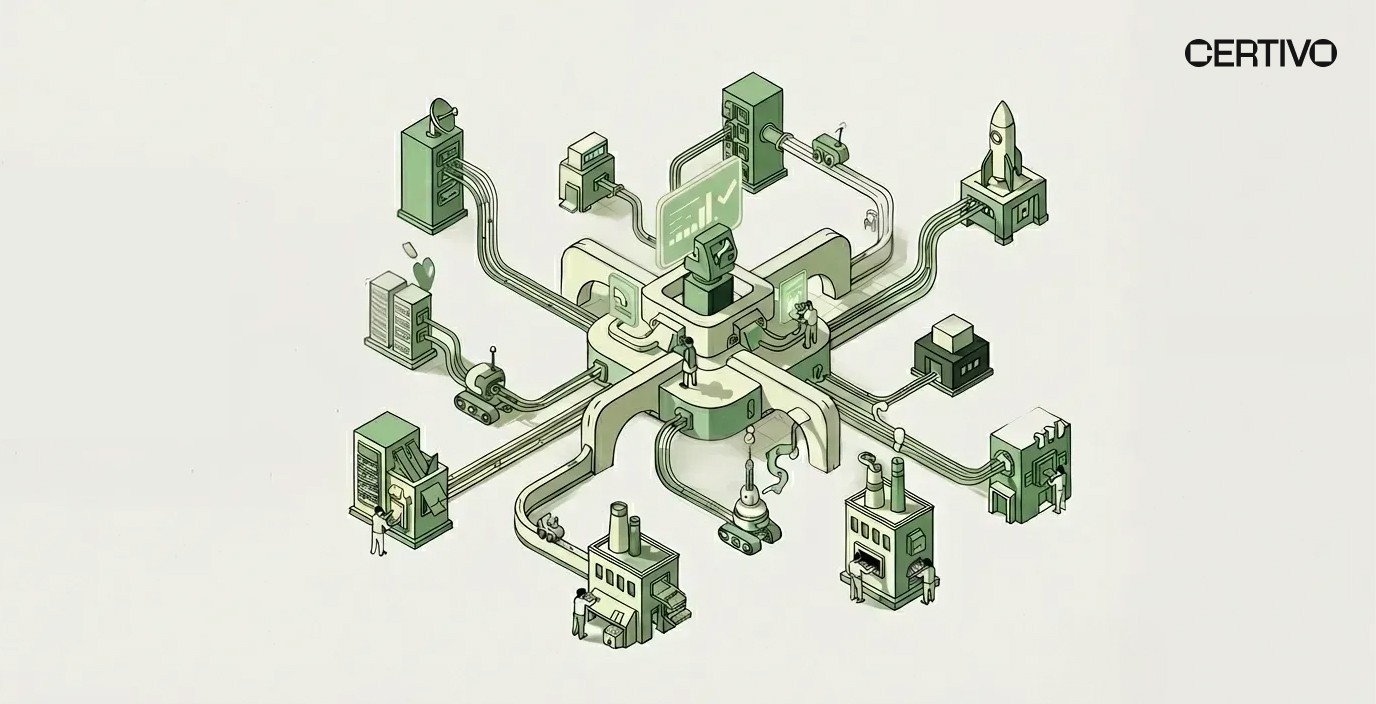

Compliance isn't just regulation—it's reputation, revenue, and readiness. With Certivo, semiconductor teams get more than checklists; they get an AI compliance assistant built to keep pace with real engineering timelines. Certivo helps semiconductor companies build traceable, secure, audit-ready processes without slowing down design cycles.

Whether you're scaling toward automotive validation or expanding into export-restricted markets, Certivo’s platform uses AI for regulatory compliance to simplify the increasingly complex landscape semiconductor teams face. From global standards to cross-border rules, our system adapts to constant change so you don’t have to.

Today’s supply chains demand visibility, speed, and accuracy. That’s why Certivo integrates artificial intelligence supply chain compliance features that help teams detect risks earlier, unify documentation, and stay aligned with partners and regulators worldwide.

Certivo also brings machine learning compliance management to the heart of engineering workflows—automating reviews, flagging incomplete evidence, and ensuring every requirement traces cleanly from design to delivery.

And when it comes to documentation, AI certificate management eliminates hours of manual tracking by keeping certifications updated, verified, and instantly retrievable for audits.

Compliance should enable innovation, not choke it. Book a demo today.

Final Thoughts

The semiconductor industry isn’t just moving fast—it’s moving under a microscope. Certifications are no longer standalone achievements; they're part of a living regulatory ecosystem that influences market access, trust, and legitimacy.

Those who treat compliance as a strategy will lead. Those who treat it as paperwork will be left behind.

Vasanth

Vasanth is a skilled Compliance Engineer with over five years of experience specializing in global environmental regulations, including REACH, RoHS, Proposition 65, POPs, TSCA, PFAS, CMRT, EMRT, FMD, and IMDS. With a strong academic foundation in Chemical Engineering from Anna University, he brings a deep technical understanding to compliance processes across complex product lines.

Vasanth excels in analyzing Bills of Materials (BOMs), evaluating supplier declarations, and ensuring regulatory conformity through meticulous review and risk assessment. He is highly proficient in supplier engagement, adept at interpreting material disclosures, and experienced in preparing customer-ready compliance documentation tailored to diverse global standards.

Known for his attention to detail, up-to-date regulatory knowledge, and proactive communication style, Vasanth plays a critical role in maintaining product compliance and advancing sustainability goals within fast-paced, globally integrated manufacturing environments.