Lavanya

Jan 6, 2026

Introduction

WEEE compliance represents one of the most critical regulatory frameworks that manufacturers and distributors must navigate today. The Waste Electrical and Electronic Equipment (WEEE) Directive establishes mandatory WEEE compliance requirements that fundamentally reshape how manufacturers approach electrical and electronic waste management across Europe and beyond.

For any organization selling electrical or electronic equipment in EU markets, achieving WEEE compliance is non-negotiable. This comprehensive guide to WEEE compliance breaks down the complex regulatory landscape, examining extended producer responsibility obligations, compliance costs, reporting requirements, and practical strategies for implementing WEEE compliance across your operations.

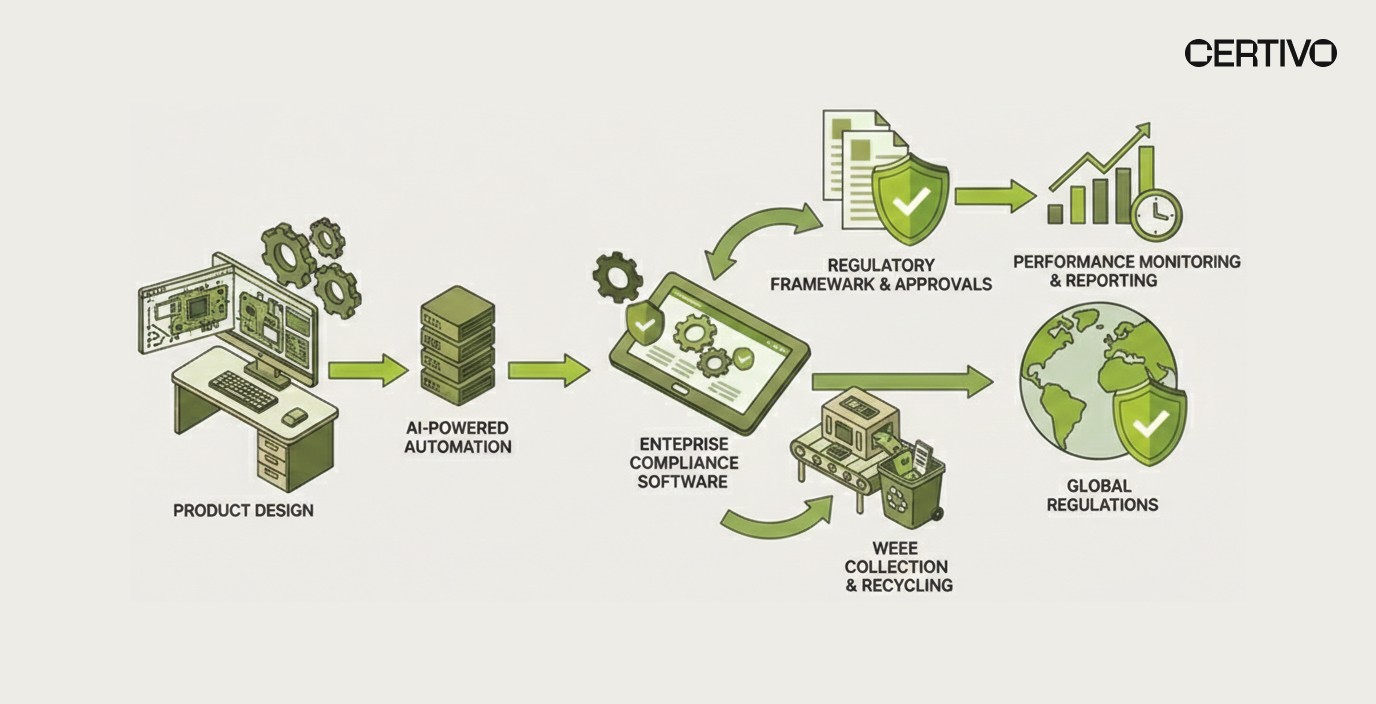

Whether you're a global electronics manufacturer entering European markets for the first time or an established producer optimizing your WEEE compliance operations, understanding WEEE compliance requirements is essential for protecting your business while managing environmental responsibility. The consequences of failing to maintain proper WEEE compliance can be severe, ranging from substantial financial penalties to supply chain disruption and reputational damage. Organizations that leverage AI-native compliance automation can significantly reduce the manual burden of managing multi-country WEEE obligations while maintaining continuous audit-ready documentation across all jurisdictions.

This blog provides everything you need to understand and implement WEEE compliance: from initial registration requirements through ongoing reporting obligations, collection infrastructure development, and advanced compliance optimization strategies.

We'll explore how to achieve WEEE compliance efficiently, navigate country-specific variations in WEEE compliance requirements, and position your organization for success in this evolving regulatory environment.

Understanding WEEE Compliance and Extended Producer Responsibility

WEEE compliance refers to adherence with the Waste Electrical and Electronic Equipment Directive (Directive 2012/19/EU and amended versions), which establishes legal requirements for managing electrical and electronic waste across European Union member states. WEEE compliance is mandatory for any manufacturer or distributor placing electrical and electronic equipment (EEE) on the market.

WEEE compliance requirements encompass multiple interconnected obligations:

Registration with national authorities and compliance schemes

Declaration of products placed on the market (PoM)

Establishment of collection infrastructure

Funding of treatment and recycling operations

Annual reporting on collection and recycling activities

Proper disposal of electrical and electronic waste

Hazardous substance management and de-pollution

WEEE compliance is not a one-time certification but an ongoing operational requirement. Manufacturers must maintain continuous WEEE compliance across all markets where products are sold, adapting to regulatory changes and evolving collection targets. Staying ahead of these shifting obligations requires robust regulatory intelligence and horizon scanning—proactively monitoring legislative updates across EU member states so your compliance posture is never reactive.

How to Achieve WEEE Compliance: The Extended Producer Responsibility Model

The cornerstone of WEEE compliance is the principle of Extended Producer Responsibility (EPR). Achieving WEEE compliance fundamentally revolves around accepting responsibility for your products throughout their entire lifecycle—not just the manufacturing and sales phases. In practical terms, EPR compliance means that producers bear direct financial and operational accountability for collection, treatment, and recycling—obligations that scale with every unit placed on the market. For a broader view of how extended producer responsibility frameworks apply across product categories, see Certivo's EPR framework overview.

Extended producer responsibility obligations require manufacturers to bear financial and operational responsibility for:

Collection of end-of-life products

Safe transportation to authorized treatment facilities

Proper de-pollution of hazardous materials

Material recovery and recycling processes

Documentation and reporting of all activities

How to achieve WEEE compliance requires integrating EPR principles into core business operations. This means designing products with end-of-life management in mind, establishing collection infrastructure, funding treatment operations, and maintaining detailed compliance records.

Why Producer Responsibility Obligation Creates Market Incentives

The producer responsibility obligation transforms waste management economics. When manufacturers directly bear the costs of recycling, they gain powerful incentives to:

Reduce material consumption and complexity

Eliminate hazardous substances beyond regulatory minimums

Design products for easier disassembly and material recovery

Minimize packaging and packaging waste

Optimize logistics for collection and reverse distribution

This market-based approach drives innovation toward circular economy models, where materials are recovered and reused rather than discarded. Manufacturers embedding design-for-compliance PLM workflows into product development can reduce material complexity and hazardous substance content at the design stage—directly lowering eco-contribution fees and simplifying end-of-life treatment.

WEEE Compliance Requirements by Country and Jurisdiction

EU WEEE Compliance Requirements Framework

The European Union establishes baseline WEEE compliance requirements through the WEEE Directive, but implementation varies significantly across member states. Manufacturers must understand both EU-wide baseline requirements and country-specific implementations to maintain proper WEEE compliance across all markets.

Mandatory Registration for WEEE Compliance

Every manufacturer achieving WEEE compliance must register with designated national authorities in each EU country where electrical and electronic equipment is placed on the market. WEEE compliance requirements for registration include:

Registration Components:

Company identification and contact information

Product categories being placed on market

Estimated quantities of electrical and electronic equipment (EEE) distributed

Proof of financial provision for waste management through compliance scheme membership or individual system

Registration Timeline: Registration must occur before placing products on the market. Failure to achieve initial WEEE compliance registration can result in:

Sales restrictions or product blocking at borders

Regulatory fines ranging from thousands to millions of euros

Exclusion from distribution channels

Mandatory back-fees and penalty interest

Put on Market (PoM) Declarations and WEEE Compliance

Manufacturers must declare the quantity of electrical and electronic equipment they "put on the market"—the total amount of products made available for distribution within a specific territory. How to achieve WEEE compliance includes accurate PoM declarations as a foundational element.

PoM declarations enable:

Baseline establishment for calculating WEEE compliance obligations

National authority tracking of product flows and market trends

Determination of producer compliance scheme fees

Producer accountability for collection and recycling targets

Regulatory assurance that manufacturers are maintaining proper WEEE compliance

Accurate PoM data depends on granular BOM-level material mapping—knowing the exact weight, material composition, and category classification of every product variant placed on each national market. Without this foundation, WEEE reporting errors and fee miscalculations become systemic.

UK WEEE Compliance Requirements Post-Brexit

Following Brexit, the United Kingdom implemented its own WEEE compliance requirements framework, broadly aligned with EU standards but with distinct operational differences affecting WEEE compliance.

UK Producer Compliance Scheme Requirements

In the UK, manufacturers achieving WEEE compliance must join one of approximately 40 approved producer compliance schemes. These schemes function as intermediaries managing compliance obligations on behalf of members, similar to collective schemes in EU countries. Each WEEE compliance scheme in the UK handles registration, WEEE reporting submissions, and evidence note management on behalf of its members—making scheme selection a critical operational decision.

UK-Specific WEEE Compliance Requirements:

Membership in approved Producer Compliance Scheme

Annual WEEE compliance registration with scheme and authorities

Declaration of products placed on market (PoM)

Payment of annual compliance scheme fees

Participation in "in-store take-back" obligations for retailers

WEEE Product Categories and Classification

10 Primary WEEE Categories Affecting Compliance

The WEEE Directive establishes 10 primary product categories, each with distinct WEEE compliance requirements and recycling obligations. Accurate product classification is essential for maintaining WEEE compliance.

Category 1: Large Household Appliances

Products: Refrigerators, washing machines, dishwashers, cookers

WEEE compliance requirements: Recovery of CFC and hazardous coolants

Collection rate: 60-70% of products sold

Category 2: Small Household Appliances

Products: Microwave ovens, toasters, coffee makers, vacuum cleaners

WEEE compliance requirements: Safe removal of hazardous components

Lower per-unit compliance costs due to smaller size

Category 3: IT and Telecommunications Equipment

Products: Computers, printers, mobile phones, servers

WEEE compliance requirements: Secure data destruction, precious metal recovery

High value recovery (gold, silver, copper content)

Category 4: Consumer Electronics

Products: Televisions, home theater systems, DVD players, cameras

WEEE compliance requirements: Screen/monitor treatment, mercury removal

Growing category affecting many manufacturers

Category 5: Lighting Equipment

Products: Fluorescent tubes, LED bulbs, compact fluorescent lamps

WEEE compliance requirements: Mercury and rare earth element management

Requires specialized de-pollution processes

Category 6: Electrical and Electronic Tools

Products: Power drills, circular saws, electric lawn mowers

WEEE compliance requirements: Battery and motor recycling

Often classified as professional equipment with different WEEE compliance rules

Category 7: Toys, Leisure, and Sports Equipment

Products: Electric toys, video game consoles, sports watches

WEEE compliance requirements: Small battery management

Growing category with lower historical recycling rates

Category 8: Medical Devices

Products: Defibrillators, dialysis machines, X-ray equipment

WEEE compliance requirements: Biohazard decontamination

Specialized handling requirements affecting WEEE compliance approach

Manufacturers in the medical device sector face overlapping regulatory obligations beyond WEEE—see Certivo's medical device compliance management guide for additional considerations.

Category 9: Monitoring and Control Equipment

Products: Thermostats, smoke detectors, measuring instruments

WEEE compliance requirements: Radioactive material management

Specialized regulatory pathways for WEEE compliance

Category 10: Automatic Dispensers

Products: Vending machines, ATMs, fuel dispensers

WEEE compliance requirements: Mechanical hazard removal

Largest weight category affecting compliance fee calculations

Impact of Accurate Classification on WEEE Compliance

Misclassification creates compliance violations:

Incorrect WEEE compliance requirements application

Significant underpayment of compliance fees

Regulatory penalties and fines

Mandatory reclassification and backdated fee adjustments

Damage to compliance credibility

Collection and Recycling Targets Under WEEE Directive

Historical and Current Collection Targets Driving WEEE Compliance

The WEEE Directive establishes progressively challenging collection and WEEE compliance requirements:

Current Target Framework (2026+):

65-85% collection target of average electrical and electronic waste weight

Specific recycling targets for material recovery (75-95% by category)

Recovery targets for hazardous substance removal (85-95%)

Producer financial accountability when collection targets fall short

What Collection Targets Mean for WEEE Compliance

Collection targets create direct financial accountability affecting WEEE compliance:

When collective collection falls short of targets, producers collectively fund shortfalls

Manufacturers with higher market share bear proportionally higher contributions

Financial penalties apply for collective non-compliance with WEEE requirements

Producer responsibility obligations increase when collection performance declines

WEEE Compliance Costs and Fee Structures

Components of WEEE Compliance Costs

Registration Fees for WEEE Compliance

One-time WEEE compliance registration fees: €500-€3,000 per country

Annual WEEE compliance renewal fees: €200-€1,000

Critical for achieving initial WEEE compliance

Producer Responsibility Organization (PRO) Membership Fees

Annual membership fees enabling WEEE compliance through schemes: €1,000-€5,000

Flat rate component providing access to national compliance infrastructure

Essential for maintaining ongoing WEEE compliance

Eco-Contributions (Per-Unit Recycling Fees)

Primary cost driver for manufacturers maintaining WEEE compliance

Calculated based on:

Product weight (in kg)

Product category (1-10 from WEEE classification)

Member state where electrical and electronic equipment is sold

Material composition and hazardous content

Typical WEEE Compliance Cost Range:

Small consumer electronics (100g): €0.05-€0.30 per unit

Medium appliances (5kg): €1.00-€5.00 per unit

Large appliances (50kg): €10.00-€50.00 per unit

Professional IT equipment: €2.00-€8.00 per unit

Administrative and WEEE Compliance Costs

PoM declaration preparation and submission: €500-€2,000 annually per country

Reporting and WEEE compliance documentation: €1,000-€5,000 annually

Compliance software or management systems: €2,000-€10,000 annually

Legal and consulting fees for WEEE compliance: €3,000-€15,000+ annually

Take-Back and Collection Infrastructure

Establishing collection points and reverse logistics for electrical and electronic waste management

Varies significantly by manufacturer's WEEE compliance approach

Range: €5,000-€100,000+ annually depending on scale

Total Cost Scenarios for WEEE Compliance

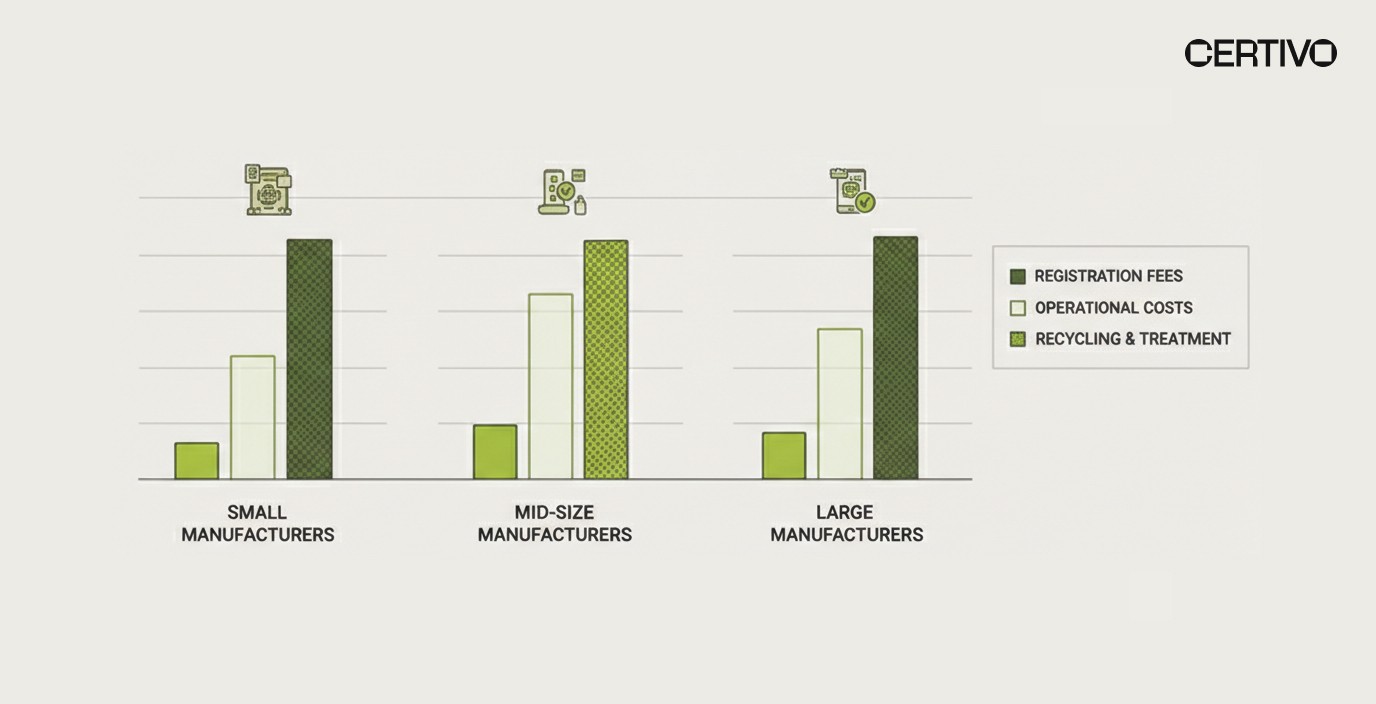

Small Manufacturer (10,000 units annually, EU only) - WEEE Compliance Budget:

Registration/membership: €3,000

Eco-contributions (average €0.50/unit): €5,000

Administrative: €2,000

Total WEEE Compliance Cost: ~€10,000 annually

Mid-Size Manufacturer (100,000 units, 5 EU countries) - WEEE Compliance Estimate:

Registration/membership (5 countries): €15,000

Eco-contributions: €30,000-€50,000

Administrative: €10,000

Total WEEE Compliance Cost: ~€55,000-€75,000 annually

Large Global Manufacturer (1,000,000+ units, 15+ countries) - Enterprise WEEE Compliance:

Registration/membership (15+ countries): €50,000-€100,000

Eco-contributions: €500,000-€1,000,000+

Administrative/consulting: €50,000-€200,000

Total WEEE Compliance Cost: €600,000-€1,300,000+ annually

For enterprises operating at this scale, Certivo's guide on cost savings through proactive compliance with AI outlines how automation reduces administrative overhead and prevents costly reporting errors across multiple jurisdictions.

Cost Reduction Strategies for Optimizing WEEE Compliance

Product Design Optimization

Reduce product weight where functionally feasible

Use materials with lower recycling complexity affecting WEEE compliance fees

Design for disassembly to improve material recovery rates

Potential savings: 10-20% of eco-contribution fees

Collective Compliance Schemes

Join group schemes rather than operating individual systems

Share infrastructure costs across multiple manufacturers

Reduced administrative overhead for WEEE compliance management

Potential savings: 20-30% vs. individual compliance operations

Take-Back Coordination

Coordinate collection with other manufacturers

Share transportation and consolidation infrastructure

Establish regional collection hubs reducing WEEE compliance costs

Potential savings: 15-25%

Digital Compliance Platforms

Implement software solutions for automated reporting

Reduce manual data entry and associated errors

Enable real-time WEEE compliance tracking

Potential savings: 10-15% on administrative costs

The most effective digital compliance platforms integrate EPR reporting software capabilities directly into existing ERP and PLM systems—creating an integrated compliance thread that auto-populates PoM declarations, calculates eco-contributions by jurisdiction, and generates audit-ready WEEE reporting outputs without manual intervention.

Registration and Reporting Obligations for WEEE Compliance

Step-by-Step Registration Process for Achieving WEEE Compliance

Step 1: Identify Applicable Countries for WEEE Compliance

Determine all EU member states where products will be sold

Consider countries where distributors will place electrical and electronic equipment on market

Account for future market expansion in WEEE compliance planning

Step 2: Register for WEEE Compliance with National Authority

Contact designated registration body (typically environmental ministry)

Compile required documentation:

Company registration and tax identification

Product descriptions and technical specifications

Product category classifications (WEEE categories 1-10)

Estimated annual quantities of electrical and electronic equipment (EEE)

Proof of financial provision for WEEE compliance

Step 3: Provide Annual PoM Declarations

At start of each calendar year, declare prior year's electrical and electronic waste quantities

Format specified by each national authority (typically online portal)

Include:

Quantity of products placed on market (in units)

Total weight of electrical and electronic equipment (in kg)

Product category distribution

Corrections or updates to prior declarations

Step 4: Pay Associated Fees

Registration fees (annual WEEE compliance renewal)

Eco-contributions based on PoM quantities

Payment typically due by specified deadline (April 30 in many countries)

Late payment penalties: 5-10% surcharge plus interest

PoM Declaration Accuracy and WEEE Compliance Integrity

Definition: "Placing on the Market" means making electrical and electronic equipment available for the first time on the market, whether manufactured locally or imported.

What Counts as PoM:

Products manufactured and sold directly

Products imported for resale

Products supplied to distributors within territory

Products supplied to retailers within territory

Accuracy Critical for WEEE Compliance:

Under-declaring creates legal liability and potential fraud charges

Audits frequently focus on PoM accuracy—companies face substantial fines for misrepresentation

Best practice: Use point-of-sale data and shipping records to substantiate declarations

Annual Reporting Requirements for Ongoing WEEE Compliance

Collection Data Reporting:

Quantity of electrical and electronic waste collected

Weight of collected materials

Delivery dates and collection facility information

Reporting frequency: Annually for WEEE compliance assurance

Recycling/Recovery Reporting:

Percentage of electrical and electronic waste materials recovered

Breakdown by material category (metals, plastics, glass)

Hazardous substance removal and treatment

Reuse vs. recycling split

Reporting requirement: Annually, typically by end of February

Streamlined WEEE reporting is essential for manufacturers operating across multiple EU jurisdictions. Purpose-built EPR reporting software consolidates PoM data, collection volumes, and recycling rates into a single platform—eliminating the spreadsheet fragmentation that causes missed deadlines and inaccurate filings. For more on replacing manual processes, see Certivo's guide on building a future-ready compliance infrastructure.

Treatment, De-Pollution, and Recycling Requirements for WEEE Compliance

Authorized Treatment Facilities and De-Pollution Processes

Collected electrical and electronic waste cannot be disposed of in landfills. Products must be transported to Authorized Treatment Facilities where specialized de-pollution and recovery processes occur as part of WEEE compliance operations.

Critical De-Pollution Requirements for WEEE Compliance:

CFC/HCFC Removal: Refrigerators and some appliances contain ozone-depleting refrigerants requiring separate capture and destruction

PCB Removal: Transformers and capacitors containing polychlorinated biphenyls require specialist extraction

Mercury Removal: Lighting products and displays contain mercury requiring careful removal

Battery Extraction: All batteries must be removed and treated separately

Asbestos Handling: Older electrical and electronic equipment may contain asbestos

Other Hazardous Components: Oil, lead, cadmium, and other hazardous materials must be isolated

The de-pollution process underscores why specialized substance reporting solutions matter—manufacturers must document exactly which hazardous materials are present in each product category to ensure treatment facilities apply the correct extraction protocols. This level of material traceability begins with thorough BOM-level data upstream in the supply chain.

Compliance Mechanisms - Individual vs. Collective Schemes

Individual Compliance Systems vs. Collective Schemes

Individual Compliance Systems for WEEE Compliance:

Definition: Manufacturer establishes and operates its own WEEE compliance system independently, without joining collective schemes.

Requirements:

Establish separate registration in each country for WEEE compliance

Establish individual collection and treatment infrastructure

Fund all collection, transportation, and recycling independently

Submit individual PoM declarations and collection reports

Maintain separate WEEE compliance documentation

Cost Structure:

Individual WEEE compliance typically 40-60% more expensive than collective schemes

Higher infrastructure costs (collection centers, logistics, staff)

Higher administrative overhead for maintaining WEEE compliance

Economies of scale only achieved at very high volumes

Collective Compliance Schemes:

Definition: Multiple manufacturers collectively establish WEEE compliance systems through shared infrastructure, typically operated by third-party administrator.

Advantages:

Significantly lower costs through shared infrastructure (40-60% savings vs. individual WEEE compliance)

Established collection network immediately available

Reduced administrative burden for WEEE compliance management

Geographic coverage across entire country/region

Better positioned to meet collection targets ensuring ongoing WEEE compliance

Whether operating through individual systems or a collective WEEE compliance scheme, manufacturers must ensure their chosen mechanism delivers continuous audit-ready documentation—maintaining verifiable records of registrations, PoM declarations, fee payments, and treatment certificates that can withstand regulatory scrutiny at any time.

Non-Compliance Risks and Penalties

Financial Penalties Across Jurisdictions

European Union Member States - WEEE Compliance Penalties:

Registration failure: €5,000-€50,000 per country

PoM declaration falsification: €10,000-€500,000

Failure to meet collection obligations: €10,000-€100,000+ per year shortfall

Improper treatment documentation: €5,000-€50,000

United Kingdom - WEEE Compliance Enforcement:

Registration/compliance scheme non-membership: Up to £50,000 fine

PoM reporting failures: Up to £50,000 fine per offense

Environmental Agency prosecution: Unlimited fines for serious breaches

Restrictions on product distribution and sales

Germany (Particularly Strict WEEE Compliance Enforcement):

Registration failures: €1,000-€5,000 per month

PoM falsification: €300,000+ criminal and civil penalties

Treatment violations: €5,000-€50,000 per incident

Business Consequences Beyond Financial Penalties

Supply Chain Disruption:

Retailers and distributors may suspend orders due to WEEE compliance concerns

Product sales may be blocked at borders

Distribution agreements cancelled

Reputational Damage:

Public disclosure of non-compliance in regulatory databases

Media coverage of significant WEEE compliance violations

Customer loss due to sustainability concerns

To understand how compliance failures cascade into broader supply chain risk, see Certivo's analysis on why ESG failure is a supply chain risk, not just a reporting issue.

Best Practices for WEEE Compliance Management

Comprehensive WEEE Compliance Management Framework

Compliance Assessment and WEEE Compliance Strategy

Conduct comprehensive WEEE compliance audit across all markets

Identify all applicable WEEE compliance requirements by product and geography

Establish baseline compliance status and identify gaps

Develop risk mitigation strategy addressing highest-risk areas

How to Achieve Sustained WEEE Compliance

Implement robust product classification system

Establish regular PoM declaration review and approval processes

Conduct quarterly collection infrastructure audits

Maintain comprehensive WEEE compliance documentation

Treatment Partner Management for WEEE Compliance

Establish formal audit protocols for treatment facility partners

Regular site visits verifying proper de-pollution processes

Monitoring of environmental compliance and certifications

Contingency planning for treatment capacity disruptions

Digital Compliance Solutions for WEEE Compliance

Automated PoM declaration preparation from sales data

Real-time WEEE compliance status dashboard

Regulatory requirement database updated for new regulations

Document management with audit trail functionality

The most effective digital compliance solutions go beyond basic reporting—they provide an integrated PLM-ERP compliance thread that connects product data, sales volumes, and regulatory requirements in a single system, ensuring that every PoM declaration and eco-contribution calculation is automatically derived from verified operational data.

How to Achieve Continuous WEEE Compliance Improvement

Developing Your WEEE Compliance Strategy

The answer to ‘How to achieve WEEE compliance’ extends beyond initial registration and basic reporting. Certivo helps you with that. Sustainable WEEE compliance requires strategic optimization:

Strategic Optimization for WEEE Compliance:

Analyze collection performance data to identify regional gaps

Evaluate compliance costs and identify reduction opportunities

Benchmark against industry standards and best performers

Implement continuous improvement initiatives

Invest in circular economy principles, reducing long-term WEEE compliance costs

Advanced WEEE Compliance Strategies:

Develop take-back programs exceeding minimum requirements

Create producer-led collection initiatives in underserved markets

Implement design-for-recycling principles reducing end-of-life complexity

Establish transparency programs communicating WEEE compliance commitment

Partner with environmental organizations amplifying sustainability credentials

For manufacturers managing WEEE alongside RoHS and REACH obligations, Certivo's RoHS and REACH compliance lessons and action steps guide provides a complementary roadmap for harmonizing substance compliance across frameworks.

Future Trends and Regulatory Evolution

Emerging WEEE Compliance Requirements

Extended Product Categories:

Continued expansion of WEEE scope to include previously unregulated categories

Growing regulatory expectations for electrical and electronic waste management

Likely future expansion affecting manufacturers' WEEE compliance obligations

Increased Collection and WEEE Compliance Targets:

Trend toward higher collection rates (85-90% by 2030)

Strengthened enforcement mechanisms and penalties

Expectation of manufacturer-funded expanded collection infrastructure

Design for Recycling and WEEE Compliance Integration:

Regulations increasingly mandate product design considerations for end-of-life

Requirements for modular design facilitating easier electrical and electronic waste recovery

Restrictions on mixed materials and composite structures difficult to separate

Digital WEEE Compliance and Reporting Evolution:

Shift toward automated, real-time WEEE compliance reporting

Blockchain technology for supply chain transparency

AI-powered anomaly detection in compliance data

Integration with broader sustainability and ESG reporting frameworks

Emerging EU requirements around digital product passports and traceability IDs will further transform WEEE compliance, requiring manufacturers to embed machine-readable product data covering material composition, recyclability, and hazardous substance content—extending traceability from production through end-of-life treatment.

Certivo provides complete WEEE compliance solutions using its AI agent CORA. Explore our features today.

Conclusion

WEEE compliance regulatory framework continues to evolve with increasingly stringent WEEE compliance requirements, higher collection targets, and expanded product categories.

For organizations navigating the WEEE regulatory framework, comprehensive WEEE compliance management solutions and expert guidance transform complex requirements into manageable, optimizable operational processes. This guide provides the strategic foundation for achieving sustainable WEEE compliance that protects your business while advancing environmental objectives.

Book a demo today at Certivo and achieve efficient and seamless WEEE compliance in no time.

Lavanya

Lavanya is an accomplished Product Compliance Engineer with over four years of expertise in global environmental and regulatory frameworks, including REACH, RoHS, Proposition 65, POPs, TSCA, PFAS, CMRT, FMD, and IMDS. A graduate in Chemical Engineering from the KLE Institute, she combines strong technical knowledge with practical compliance management skills across diverse and complex product portfolios.

She has extensive experience in product compliance engineering, ensuring that materials, components, and finished goods consistently meet evolving international regulatory requirements. Her expertise spans BOM analysis, material risk assessments, supplier declaration management, and test report validation to guarantee conformity. Lavanya also plays a key role in design-for-compliance initiatives, guiding engineering teams on regulatory considerations early in the product lifecycle to reduce risks and streamline market access.

Her contributions further extend to compliance documentation, certification readiness, and preparation of customer deliverables, ensuring transparency and accuracy for global stakeholders. She is adept at leveraging compliance tools and databases to efficiently track regulatory changes and implement proactive risk mitigation strategies.

Recognized for her attention to detail, regulatory foresight, and collaborative approach, Lavanya contributes significantly to maintaining product compliance, safeguarding brand integrity, and advancing sustainability goals within dynamic, globally integrated manufacturing environments.