Lavanya

Feb 3, 2026

The European Union has introduced stringent new disclosure and usage requirements for recovered rigid PVC containing lead, creating immediate EU RoHS recovered PVC lead compliance obligations for manufacturers of electrical and electronic equipment. Directive (EU) 2024/232, which entered into force on August 1, 2024, establishes mandatory labelling requirements that take technical effect on May 28, 2026, fundamentally changing how manufacturers handle recycled materials in their products.

This regulation represents a significant shift in how the EU balances circular economy objectives with human health protection. While exemptions permit continued use of recovered PVC containing residual lead and cadmium, manufacturers must now provide specific public disclosures and limit material applications to designated categories. Organizations without robust regulatory change monitoring capabilities face audit exposure, market access disruption, and supply chain complications as this deadline approaches.

Table of Contents

Understanding Directive 2024/232 and Its Regulatory Context

Key Requirements and Compliance Timeline

Mandatory Disclosure and Labelling Specifications

Usage Restrictions for Recovered PVC Materials

Industries and Products Facing Direct Impact

Supply Chain and Audit Documentation Requirements

Compliance Risks and Enforcement Implications

Strategic Preparation Checklist for May 2026

How AI Transforms RoHS Compliance Management

Understanding Directive 2024/232 and Its Regulatory Context

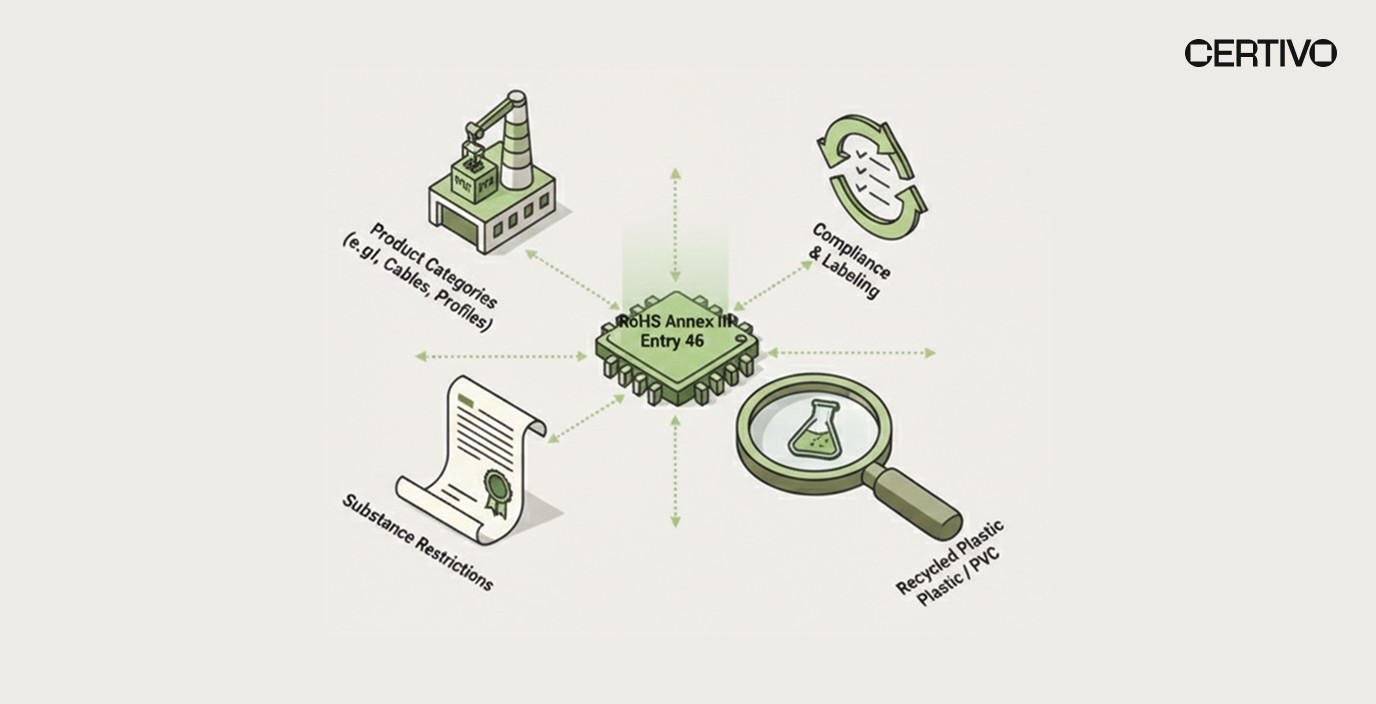

Directive (EU) 2024/232 amends the RoHS framework by adding Entry 46 to Annex III, establishing specific conditions under which recovered rigid PVC containing lead may continue to be used in electrical and electronic equipment. The Official Journal of the EU publication of Directive 2024/232 provides the authoritative legal text governing these requirements.

The regulation reflects the EU's ongoing effort to balance environmental sustainability through circular economy principles with stringent human health protections. Recovered PVC from electrical and electronic windows and doors often contains legacy lead content from historical manufacturing processes. Rather than prohibiting recycling entirely, the EU permits continued use under controlled conditions that ensure transparency and limit exposure pathways.

EU RoHS recovered PVC lead compliance intersects with broader regulatory developments affecting electronics manufacturers. This milestone coincides with the 2025/2026 restructuring of general lead exemptions under entries 6, 7a, and 7c, signalling a trend toward more granular substance tracking requirements. Organizations should view this regulation within the context of evolving RoHS compliance requirements affecting the electronics industry.

The regulation applies across all EU member states, creating uniform compliance obligations regardless of where products enter the European market. Manufacturers, importers, and distributors placing covered products on EU markets share responsibility for ensuring compliance with labelling and usage restrictions.

Key Requirements and Compliance Timeline

The directive establishes clear timelines and specific requirements that manufacturers must understand to achieve EU RoHS recovered PVC lead compliance before enforcement begins.

Critical Dates Summary

Milestone | Date | Requirement |

|---|---|---|

Entry Into Force | August 1, 2024 | Directive officially effective |

Technical Application | May 28, 2026 | Full compliance required |

Documentation Readiness | Ongoing | EN 15343:2007 certificates required |

August 1, 2024: Directive Entry Into Force

The directive officially entered into force on this date, establishing the legal framework for subsequent compliance requirements. While technical application occurs later, manufacturers should have begun preparation activities immediately following this date.

May 28, 2026: Technical Application Deadline

This date marks when all covered products placed on EU markets must meet mandatory disclosure, labelling, and usage restriction requirements. Products containing recovered rigid PVC with lead concentration at or above 0.1% must display required markings by this deadline.

Organizations relying on manual compliance tracking face significant challenges meeting this timeline. Building future-ready compliance infrastructure enables systematic preparation rather than last-minute scrambles.

Mandatory Disclosure and Labelling Specifications

The directive establishes precise recovered PVC labelling requirements that manufacturers must implement for products containing lead at specified concentrations. Understanding these specifications ensures compliant marking practices.

Required Disclosure Statement

Any article containing recovered rigid PVC with a lead concentration at or above 0.1% must be marked with the following statement:

"Contains ≥0.1% lead"

This disclosure requirement creates transparency for downstream users, recyclers, and consumers regarding lead content in recovered materials. The statement must be exact and cannot be modified or paraphrased.

Formatting Requirements

The directive specifies how markings must appear to ensure effective communication:

Visible: Marking must be readily observable without requiring disassembly or special equipment

Legible: Text must be clear and readable under normal viewing conditions

Indelible: Marking must remain permanent throughout the product's service life

Alternative Marking Provisions

When product size or nature prevents direct marking on the article itself, the disclosure statement must be placed on the packaging. This provision accommodates small components and products where direct marking proves impractical while maintaining disclosure objectives.

Compliance and regulation managers should evaluate product portfolios to determine which items require direct marking versus packaging-based disclosure.

Usage Restrictions for Recovered PVC Materials

Beyond labelling requirements, EU RoHS recovered PVC lead compliance includes specific limitations on where recovered materials may be used. These restrictions ensure lead-containing recycled PVC reaches only appropriate applications.

Source Material Restrictions

The regulation specifically addresses recovered rigid PVC from electrical and electronic windows and doors. This material category commonly contains legacy lead content from stabilizers used in historical manufacturing processes.

Permitted Application Categories

Recovered rigid PVC from covered sources must only be reused in specific categories aligned with REACH Entry 63, points 18a-d. This alignment creates consistency across EU chemical regulatory frameworks while limiting potential exposure pathways.

Manufacturers must verify that their intended applications fall within permitted categories before incorporating recovered PVC materials. Applications outside designated categories face prohibition regardless of labelling compliance.

Circular Economy Context

The regulation demonstrates how the EU balances sustainability objectives with health protection. Rather than prohibiting recycling of lead-containing PVC, the framework enables continued circular economy participation under controlled conditions. This approach acknowledges the environmental benefits of material recovery while implementing safeguards.

Understanding these usage restrictions requires multi-tier supply chain transparency to verify that recovered materials meet both source and application requirements throughout manufacturing processes.

Industries and Products Facing Direct Impact

The directive creates EU RoHS recovered PVC lead compliance obligations across multiple industry sectors utilizing recovered PVC in electrical and electronic equipment manufacturing.

Electrical and Electronic Equipment Manufacturers

EEE manufacturers incorporating recovered rigid PVC face direct compliance obligations. Product categories include:

Consumer electronics with PVC housings or components

Industrial control equipment utilizing recycled materials

Lighting equipment incorporating recovered PVC elements

Household appliances with recycled plastic components

Construction and Building Electronics

Window and door electronics, including automated systems, sensors, and control units integrated with PVC frames, face particular scrutiny given the source material focus on electrical and electronic windows and doors.

Cable and Wire Manufacturers

Cable insulation and jacketing frequently utilize PVC materials. Manufacturers incorporating recovered PVC in cable products must evaluate lead content and implement appropriate labelling.

Component Suppliers

Suppliers of PVC components to EEE manufacturers share compliance responsibility. The industrial electronics industry must establish verification processes ensuring materials meet requirements before reaching downstream customers.

Supply Chain and Audit Documentation Requirements

EU RoHS recovered PVC lead compliance creates significant documentation obligations that organizations must address to demonstrate regulatory adherence during audits and market surveillance activities.

EN 15343:2007 Certification Requirements

Suppliers must maintain documentary evidence substantiating the "recovered" origin of PVC materials. EN 15343:2007 certificates provide the standardized documentation format that auditors and enforcement authorities recognize for verifying recycled content claims.

This certification requirement creates supply chain verification obligations extending beyond simple supplier declarations. Manufacturers must collect, verify, and retain certificates from material suppliers as part of continuous audit-ready documentation practices.

Lead Content Verification

Manufacturers must verify lead content of recycled components before market placement. This verification requirement creates testing obligations or documentation collection workflows ensuring lead concentration data accompanies recovered materials through supply chains.

Streamlined supplier documentation processes become essential when managing certification and testing data across multiple material suppliers.

Traceability Requirements

The combination of source restrictions, usage limitations, and labelling requirements creates comprehensive traceability obligations. Manufacturers must demonstrate that:

Recovered PVC originates from permitted source categories

Lead content has been verified and documented

Materials reach only permitted application categories

Appropriate labelling appears on final products

BOM-level compliance intelligence enables systematic tracking of material origins and compliance status throughout manufacturing processes.

Compliance Risks and Enforcement Implications

Non-compliance with recovered PVC labelling requirements carries significant consequences that organizations must understand when prioritizing compliance investments and resource allocation.

Market Access Disruption

Products failing to meet labelling or usage restriction requirements face potential market withdrawal from EU markets. For manufacturers with significant European revenue exposure, non-compliance threatens commercial operations rather than merely creating regulatory friction.

Audit Exposure

The documentation requirements create audit vulnerabilities for organizations lacking systematic certificate collection and retention practices. Enforcement authorities may request EN 15343:2007 certificates and lead verification documentation during market surveillance activities.

Supply Chain Liability

Manufacturers bear responsibility for compliance regardless of whether non-conformance originates with material suppliers. Organizations must implement supplier qualification and ongoing monitoring processes that verify compliance before materials enter production.

Transitional Alignment Risks

This regulation coincides with broader 2025/2026 restructuring of general lead exemptions under RoHS entries 6, 7a, and 7c. Organizations should view compliance preparation within this broader context, as EU RoHS exemption changes create interconnected compliance obligations.

Understanding why compliance teams should drive innovation helps organizations avoid enforcement consequences that reactive compliance approaches create.

Strategic Preparation Checklist for May 2026

Organizations should implement systematic preparation activities to achieve EU RoHS recovered PVC lead compliance before the May 28, 2026 technical application deadline.

Material Inventory Assessment

Identify all products containing recovered rigid PVC

Determine lead concentration levels in recovered materials

Evaluate whether materials originate from permitted source categories

Assess intended applications against permitted usage categories

Supplier Qualification Activities

Request EN 15343:2007 certificates from recovered PVC suppliers

Collect lead content verification documentation

Verify supplier testing and certification processes

Establish ongoing monitoring for supplier compliance status

Labelling Implementation

Design compliant disclosure markings meeting formatting requirements

Determine marking placement for each product type

Implement packaging-based alternatives where direct marking proves impractical

Establish quality controls ensuring marking durability and legibility

Documentation System Enhancement

Implement certificate collection and retention systems

Establish traceability linking materials to certifications

Create audit response procedures for enforcement inquiries

Develop continuous audit-ready documentation practices

Replacing spreadsheets with scalable systems enables systematic management of certification and verification documentation across supplier networks.

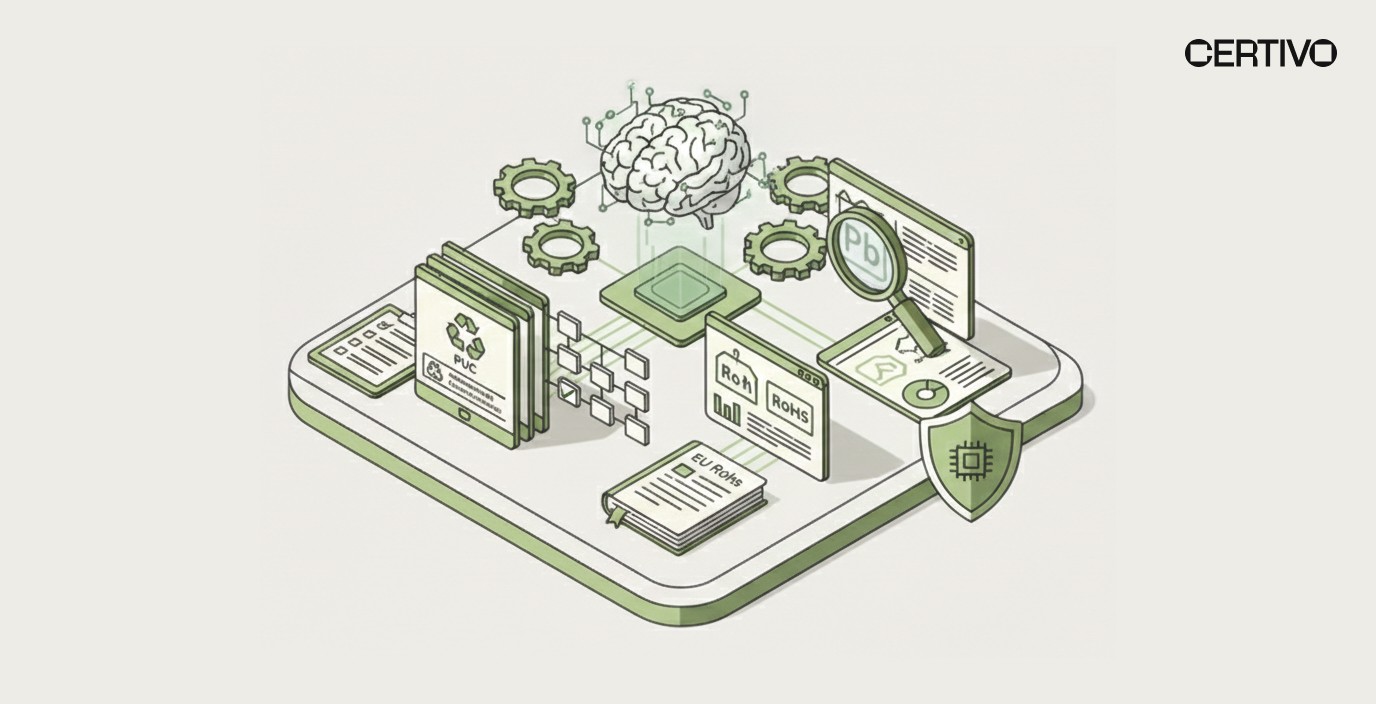

How AI Transforms RoHS Compliance Management

Manual compliance approaches cannot scale to address the complexity of EU RoHS recovered PVC lead compliance across extensive product portfolios and global supply chains. AI compliance software electronics manufacturers deploy fundamentally transforms organizational capabilities for regulatory monitoring, documentation management, and supplier verification.

Intelligent Regulatory Monitoring

RoHS regulatory landscapes evolve continuously as the EU updates exemptions, adds new restrictions, and clarifies enforcement approaches. Automated regulatory monitoring RoHS capabilities track developments across the framework, alerting compliance teams to changes requiring response.

Understanding why people-only compliance cannot scale helps executives appreciate strategic value of AI-powered monitoring operating continuously across regulatory domains.

Automated Supplier Data Collection

Supplier certification and verification data collection creates significant administrative burden when managed manually. Certivo's CORA, an intelligent AI agent, automates supplier follow-ups and data completion workflows. Rather than manual email chasing, CORA systematically engages suppliers to collect EN 15343:2007 certificates and lead verification documentation.

BOM-Level Compliance Intelligence

Product bills of materials require systematic analysis to identify components containing recovered PVC and verify compliance status. AI platforms enable BOM-level compliance intelligence that flags materials requiring attention and tracks compliance status throughout product lifecycles.

Continuous Audit-Ready Documentation

Compliance documentation must demonstrate current practices aligned with EEE recycled materials compliance requirements. AI platforms maintain audit-ready documentation that evolves as regulations change, eliminating the scramble that typically precedes enforcement inquiries.

Effective supplier collaboration becomes systematic rather than episodic when supported by AI-powered compliance platforms.

Conclusion: Strategic Imperatives for May 2026 Readiness

Directive (EU) 2024/232 establishes significant new obligations for EU RoHS recovered PVC lead compliance that electronics manufacturers must address before the May 28, 2026 technical application deadline. The mandatory disclosure statement "Contains ≥0.1% lead" must appear on products containing recovered rigid PVC at specified concentration levels, with formatting requirements ensuring visibility, legibility, and permanence.

Beyond labelling, the regulation creates usage restrictions limiting where recovered PVC may be applied, documentation requirements demanding EN 15343:2007 certificates, and supply chain lead content verification obligations that extend compliance responsibility throughout material supply networks. Organizations viewing these requirements in isolation risk missing the broader regulatory context, as this milestone coincides with restructuring of general lead exemptions signalling continued evolution of EU substance tracking requirements.

The circular economy compliance EU framework enables continued recycling of lead-containing PVC under controlled conditions rather than prohibiting recovery entirely. This approach acknowledges environmental benefits of material recovery while implementing safeguards protecting human health. Manufacturers embracing this framework gain competitive advantages through sustainable material sourcing while meeting compliance obligations.

The complexity of managing certification collection, lead verification, labelling implementation, and usage restriction compliance across extensive product portfolios exceeds what manual processes can reliably manage. Organizations investing in AI compliance software electronics solutions reduce compliance costs while improving accuracy and audit readiness.

Executive leadership must recognize that EU RoHS recovered PVC lead compliance represents one element of ongoing regulatory evolution affecting electronics manufacturers. Building robust compliance infrastructure today positions organizations to address not only this directive but continuing development of EU substance restrictions and circular economy requirements.

Explore how Certivo's AI-powered compliance platform can help your organization achieve continuous audit-ready documentation and multi-tier supply chain transparency for RoHS compliance requirements.

Lavanya

Lavanya is an accomplished Product Compliance Engineer with over four years of expertise in global environmental and regulatory frameworks, including REACH, RoHS, Proposition 65, POPs, TSCA, PFAS, CMRT, FMD, and IMDS. A graduate in Chemical Engineering from the KLE Institute, she combines strong technical knowledge with practical compliance management skills across diverse and complex product portfolios.

She has extensive experience in product compliance engineering, ensuring that materials, components, and finished goods consistently meet evolving international regulatory requirements. Her expertise spans BOM analysis, material risk assessments, supplier declaration management, and test report validation to guarantee conformity. Lavanya also plays a key role in design-for-compliance initiatives, guiding engineering teams on regulatory considerations early in the product lifecycle to reduce risks and streamline market access.

Her contributions further extend to compliance documentation, certification readiness, and preparation of customer deliverables, ensuring transparency and accuracy for global stakeholders. She is adept at leveraging compliance tools and databases to efficiently track regulatory changes and implement proactive risk mitigation strategies.

Recognized for her attention to detail, regulatory foresight, and collaborative approach, Lavanya contributes significantly to maintaining product compliance, safeguarding brand integrity, and advancing sustainability goals within dynamic, globally integrated manufacturing environments.