Vasanth

Jan 27, 2026

Manufacturing executives investing in digital transformation face a critical decision that will determine whether their initiatives deliver value or create expensive technical debt: where to begin. The conventional playbook starts with ERP modernization and PLM implementation. The most successful organizations, however, start with something entirely different—compliance automation digital transformation.

This counterintuitive approach recognizes a fundamental reality: operational systems can only create value when products can legally reach customers. Before optimizing production efficiency or centralizing product data, manufacturers must establish the regulatory intelligence enterprise systems and market readiness digital transformation capabilities through an AI-powered compliance platform architecture that determines whether optimized products will pass audits and clear customs.

Compliance automation digital transformation isn't a downstream consequence of enterprise system modernization—it's the essential first step that enables everything else to deliver meaningful business value through BOM-level regulatory compliance and multi-tier supplier risk visibility.

Table of Contents

The Digital Transformation Sequencing Problem

Why ERP PLM Integration Compliance Data Falls Short

The Hidden Cost of Compliance Debt

How Compliance Complexity Derails Digital Initiatives

The Compliance-First Digital Architecture

AI-Powered Compliance Platform Architecture as Integration Hub

Business Outcomes From Market Readiness Digital Transformation

Building Your Supply Chain Compliance Automation Roadmap

The Digital Transformation Sequencing Problem

Why Traditional IT Modernization Fails Without Compliance Automation

Most digital transformation initiatives follow a predictable sequence: modernize ERP for financial visibility, implement PLM for product data management, add analytics for operational insights, then address compliance requirements through bolt-on modules or spreadsheets.

This approach assumes operational efficiency precedes market access. Reality operates differently when compliance automation digital transformation is treated as an afterthought rather than a foundation.

A manufacturer with perfect inventory visibility into materials that cannot be sold due to PFAS restrictions has optimized the wrong problem. An engineering team with sophisticated ERP PLM integration compliance data designing products with RoHS-banned substances has digitized a fundamentally broken process that lacks BOM-level regulatory compliance.

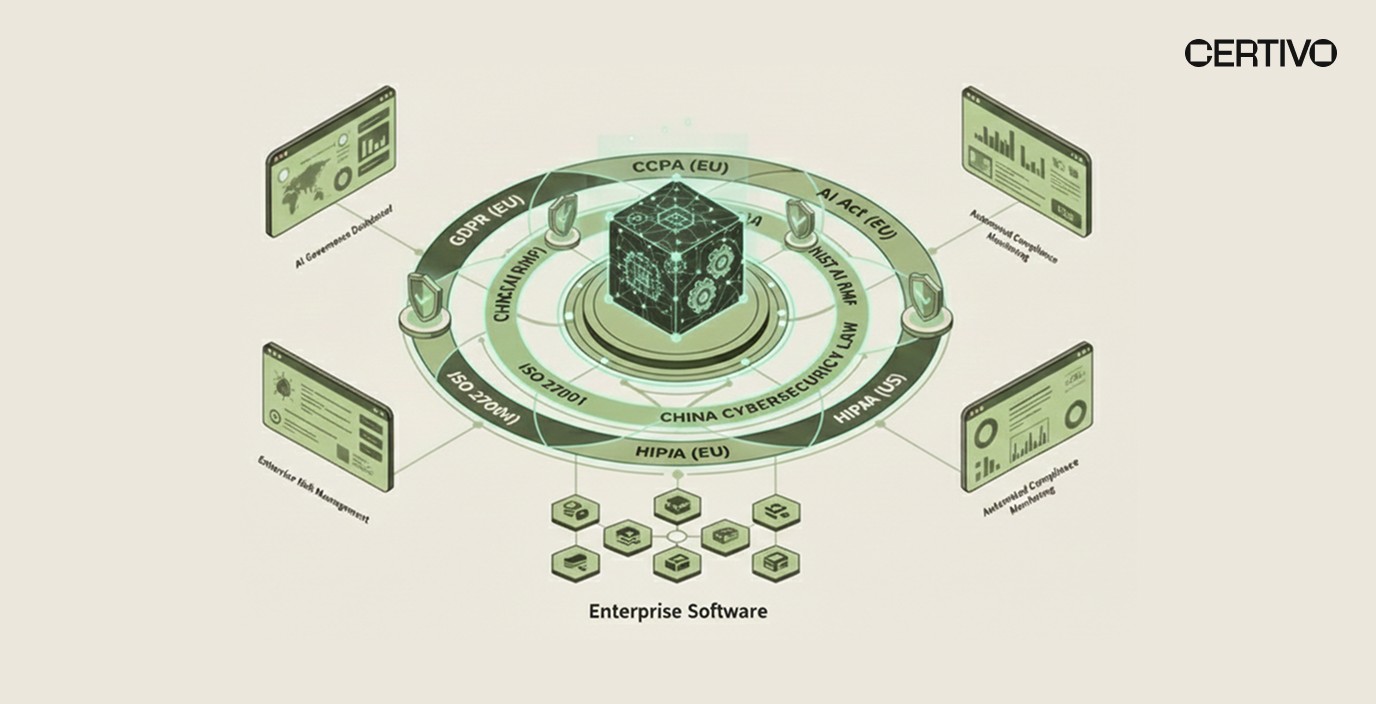

The Regulatory Environment Demands AI-Powered Compliance Platform Architecture

Enterprise systems designed for pre-regulatory manufacturing eras cannot handle today's supply chain compliance automation requirements:

Real-time regulatory monitoring across dozens of jurisdictions through regulatory intelligence enterprise systems

Substance-level material analysis beyond part-number tracking for BOM-level regulatory compliance

Multi-tier supplier visibility into sub-material composition for multi-tier supplier risk visibility

Predictive risk assessment for proposed regulations through AI-powered compliance platform architecture

Traditional ERP and PLM platforms track what you manufacture. AI-powered compliance platforms determine where you can sell it through comprehensive market readiness digital transformation capabilities.

Why ERP PLM Integration Compliance Data Falls Short

The Data Granularity Problem in Market Readiness Digital Transformation

ERP systems excel at transactional efficiency—purchase orders, inventory movements, production schedules. PLM systems centralize engineering data—CAD files, BOMs, change orders. Neither was architected for the granularity that compliance automation digital transformation requires through AI-powered compliance platform architecture.

Compliance operates at the substance level. Regulations don't restrict "plastic housing part #12345." They restrict specific chemical compounds—phthalates at 0.1% by weight, PFAS at parts-per-billion thresholds, lead in concentrations exceeding exemption limits.

BOM-level compliance intelligence requires substance composition data that ERP PLM integration compliance data systems don't capture, validate, or analyze for BOM-level regulatory compliance. Organizations seeking proactive risk management discover that enterprise systems lack the granular visibility necessary for modern compliance requirements.

The Unstructured Data Challenge in Supply Chain Compliance Automation

The information compliance teams actually need for compliance automation digital transformation exists outside enterprise systems:

Supplier declarations in varying formats

Mill test reports as scanned PDFs

Material safety data sheets with incomplete fields

Third-party test results in proprietary formats

Email chains containing critical certifications

ERP and PLM systems manage structured transactional data. Supply chain compliance automation requires processing unstructured supplier documentation at scale—exactly what AI-powered automation platforms were designed to handle through AI-powered compliance platform architecture. Modern supplier documentation workflows must accommodate this complexity while maintaining data integrity across the enterprise.

The Regulatory Change Velocity Gap

Enterprise systems update on planned release cycles—quarterly patches, annual major upgrades. Regulatory intelligence enterprise systems must evolve continuously to support market readiness digital transformation initiatives.

REACH SVHC additions happen twice yearly while China RoHS 2.0 implementation deadlines shift unpredictably. Static compliance modules cannot keep pace with market readiness digital transformation needs, making real-time monitoring essential for maintaining compliance across multiple jurisdictions.

The Hidden Cost of Delaying Compliance Automation Digital Transformation

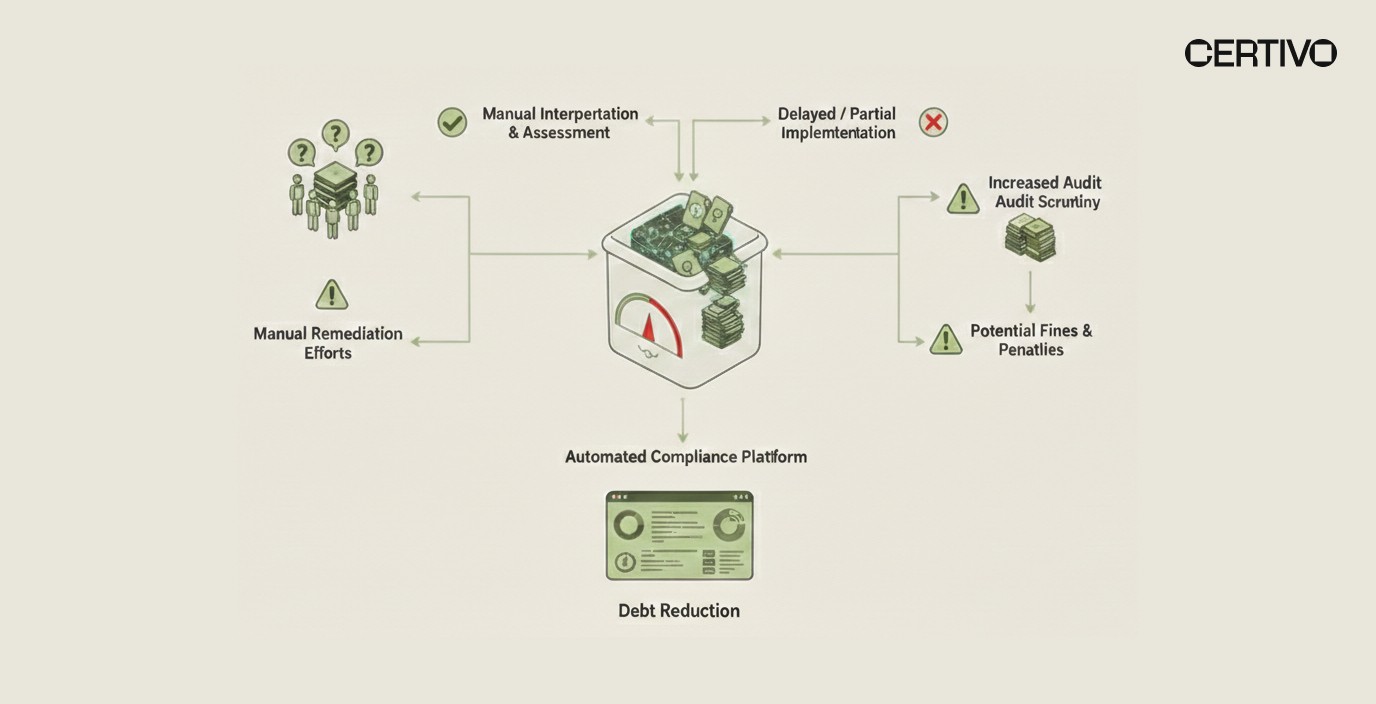

Understanding Compliance Debt

Software teams understand technical debt—shortcuts creating future maintenance burdens. Manufacturing faces compliance debt—the accumulated gap between regulatory requirements and an organization's ability to demonstrate conformance at market velocity through compliance automation digital transformation.

Compliance debt compounds invisibly through decisions that seem reasonable initially but create exponential challenges. Every product designed without substance analysis for BOM-level regulatory compliance adds to future burden. Every supplier onboarded without comprehensive data collection for multi-tier supplier risk visibility increases organizational risk exposure.

How Legacy Systems Compound the Problem

Traditional enterprise systems actively create compliance debt despite significant investments in ERP PLM integration compliance data infrastructure:

Siloed Data: Compliance information scattered across purchasing databases, quality systems, engineering repositories, and email creates reconciliation nightmares during audits. Organizations lacking centralized compliance visibility struggle to respond quickly to customer inquiries or regulatory investigations.

Manual Validation: Without automated analysis through supply chain compliance automation, compliance teams manually review supplier declarations—a process that doesn't scale when managing hundreds of suppliers and thousands of components requiring BOM-level regulatory compliance verification.

Reactive Response: Legacy systems document compliance status but don't predict risks from proposed regulations or flag emerging supplier issues before they impact production through regulatory intelligence enterprise systems.

Organizations attempting to retrofit compliance into ERP and PLM implementations discover that compliance automation digital transformation requires fundamentally different architecture—purpose-built for regulatory intelligence, not operational transactions. The gap becomes apparent when audit preparation requires weeks of manual documentation assembly instead of instant report generation.

How Compliance Complexity Derails Digital Initiatives

The Integration Bottleneck

Digital transformation initiatives promise integration benefits—single source of truth, automated workflows, real-time visibility. Compliance requirements expose the limitations when compliance automation digital transformation isn't prioritized from the start.

Consider a typical scenario: A manufacturer implements new ERP and PLM systems, invests months in data migration and process redesign, then discovers their supplier compliance documentation workflow still depends on emails requesting declarations, manual review of inconsistent formats, spreadsheet tracking of submission status, shared drives for document storage, and ad hoc queries during customer audits.

The digital transformation delivered operational improvements while leaving the compliance bottleneck untouched—because enterprise systems weren't designed to solve supply chain compliance automation challenges. Organizations need scalable systems that process supplier data regardless of format or source while maintaining multi-tier supplier risk visibility.

The Market Readiness Delay

Organizations pursuing international expansion or new customer segments discover that operational readiness precedes market readiness digital transformation by months or years without proper AI-powered compliance platform architecture.

You cannot demonstrate REACH compliance without substance-level supplier data enabled through BOM-level regulatory compliance systems. You cannot prove conflict minerals due diligence without multi-tier supplier risk visibility into your extended supply chain.

Digital transformation initiatives that ignore compliance automation digital transformation infrastructure create the illusion of readiness while delaying actual market access. Companies seeking to expand into new markets faster must establish compliance capabilities before pursuing geographic growth.

The Audit Failure Cascade

Sophisticated ERP and PLM systems cannot prevent audit findings when the underlying compliance data doesn't exist or cannot be quickly retrieved through regulatory intelligence enterprise systems.

Common audit failures include inability to trace materials to specific suppliers, missing or expired supplier certifications, incomplete substance declarations for critical components, and outdated compliance assessments for regulatory changes. These failures occur despite significant IT investments because audit readiness requires compliance-specific capabilities that general-purpose enterprise systems don't provide for BOM-level regulatory compliance verification.

The Compliance-First Digital Architecture

Starting With the Foundation for Compliance Automation Digital Transformation

Compliance automation digital transformation inverts the traditional sequence:

Phase 1: Establish AI-powered compliance platform architecture as foundation

Phase 2: Integrate compliance intelligence with existing systems through ERP PLM integration compliance data

Phase 3: Modernize ERP/PLM with compliance data as prerequisite

Phase 4: Build analytics leveraging compliance as strategic asset for market readiness digital transformation

This approach recognizes that supply chain compliance automation isn't a downstream consideration—it's the data foundation enabling everything else through regulatory intelligence enterprise systems.

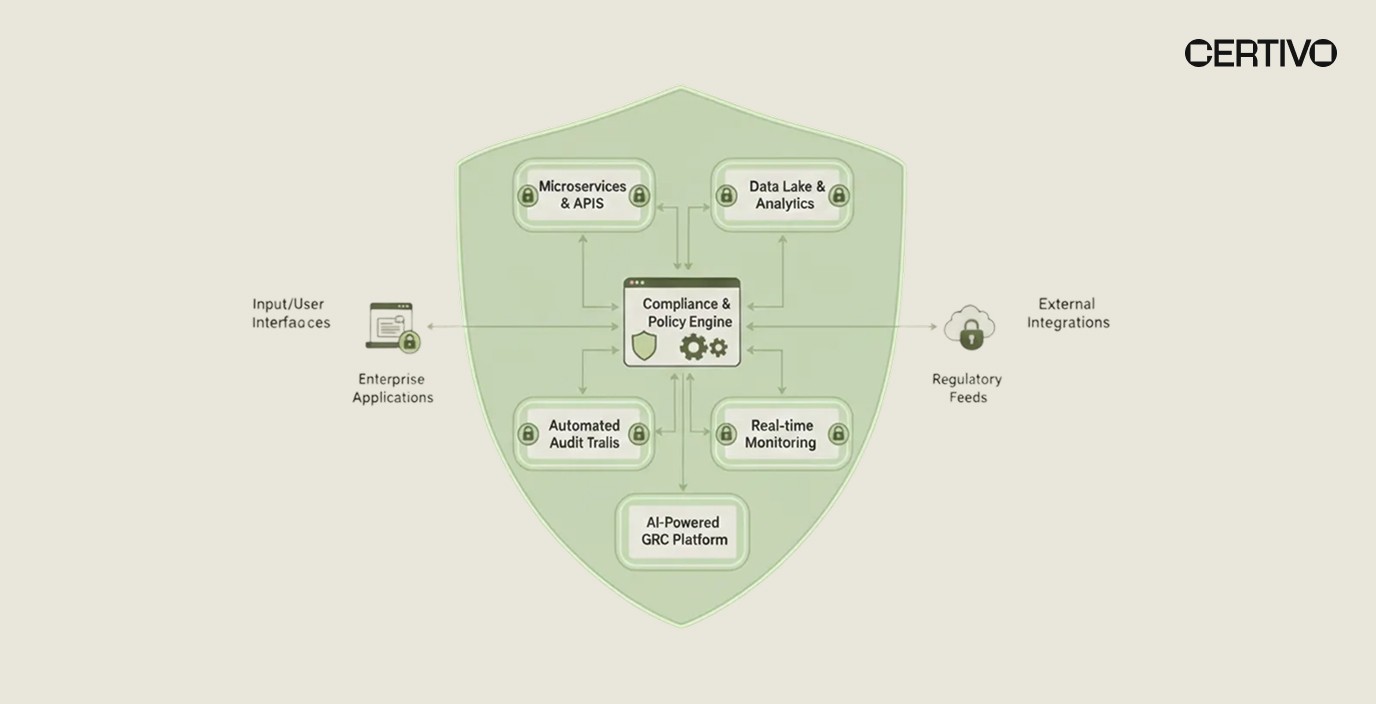

Key Architectural Components

A compliance-first architecture requires specific capabilities for compliance automation digital transformation:

Automated Data Collection:

AI agents automatically request, collect, and validate supplier documentation—eliminating manual follow-up while ensuring data completeness for multi-tier supplier risk visibility. Modern platforms enable supplier collaboration without overwhelming internal teams with coordination overhead.

Intelligent Document Processing:

Computer vision and natural language processing extract substance data from unstructured formats—PDFs, scanned images, emails—regardless of supplier sophistication, enabling comprehensive BOM-level regulatory compliance across diverse supplier bases.

Regulatory Intelligence Engine:

Real-time monitoring of global regulatory changes through regulatory intelligence enterprise systems automatically updates compliance requirements and flags affected products before deadlines, supporting market readiness digital transformation initiatives.

BOM-Level Analysis:

Substance composition analysis at component and sub-material levels identifies compliance risks that part-number tracking misses, providing the granular BOM-level regulatory compliance visibility that modern markets demand.

Multi-Tier Visibility:

Supply chain mapping beyond direct suppliers reveals hidden risks in sub-tier material composition, delivering the multi-tier supplier risk visibility that major OEMs increasingly require from their suppliers.

These capabilities form the intelligent layer that enterprise systems depend on but cannot deliver themselves for compliance automation digital transformation.

AI-Powered Compliance Platform Architecture as Integration Hub

The Central Intelligence Model

Rather than bolting compliance onto enterprise systems, forward-thinking organizations position AI-powered compliance platform architecture as the central intelligence hub that enterprise systems consume for compliance automation digital transformation.

This model recognizes different systems serve different purposes:

ERP: Transactional efficiency and financial control

PLM: Engineering collaboration and product data management

Compliance Platform: Regulatory intelligence enterprise systems and market readiness digital transformation validation

The AI-powered compliance platform architecture becomes the authoritative source for supplier qualification status, material composition data, regulatory requirement mapping, compliance risk scoring, and audit documentation necessary for BOM-level regulatory compliance.

Integration Patterns That Work

Successful ERP PLM integration compliance data strategies follow proven patterns:

Bidirectional Data Exchange:

Supplier master data and BOMs flow from ERP/PLM to compliance platform for supply chain compliance automation. Compliance status and risk scores flow back to inform procurement and engineering decisions, ensuring BOM-level regulatory compliance throughout the product lifecycle.

Event-Driven Updates:

Regulatory changes trigger automatic reassessment of affected products through regulatory intelligence enterprise systems. Compliance status changes block or release purchase orders without manual intervention, enabling true compliance automation digital transformation across enterprise workflows.

Embedded Validation:

Compliance checks embedded in engineering change and supplier onboarding workflows prevent non-compliant decisions at the point of entry, supporting market readiness digital transformation through proactive risk prevention.

This architecture delivers benefits impossible with traditional approaches—operational systems gain intelligence they lack while maintaining their core transactional focus. Organizations can launch new products faster when compliance validation happens automatically during development rather than as a post-design checkpoint.

The API-First Advantage

Modern compliance platforms built on API-first AI-powered compliance platform architecture enable flexibility impossible with monolithic ERP modules:

Connect to multiple ERP instances across business units for consistent supply chain compliance automation

Integrate with specialized industry systems requiring BOM-level regulatory compliance data

Enable custom workflows without core system modifications

Support phased rollouts and pilot programs for compliance automation digital transformation

Organizations can establish compliance infrastructure before committing to enterprise-wide ERP replacement—reducing risk and proving value before larger investments. The ability to respond faster to customer RFQs through instant compliance documentation access demonstrates immediate ROI for market readiness digital transformation initiatives.

Business Outcomes From Market Readiness Digital Transformation

Accelerated Market Access Through Compliance Automation Digital Transformation

Organizations starting with compliance automation digital transformation achieve market readiness digital transformation months faster than those retrofitting compliance into operational systems.

Specific outcomes include:

Faster Product Launches:

Automated compliance validation during development prevents costly redesigns discovered during customer qualification, enabling organizations to launch products with confidence in their BOM-level regulatory compliance status across target markets.

Rapid Geographic Expansion:

Comprehensive substance databases enable quick assessment of regulatory requirements for new markets without manual supplier data collection, accelerating market readiness digital transformation through existing multi-tier supplier risk visibility infrastructure.

Streamlined Customer Onboarding:

Complete compliance documentation instantly available for customer audits and RFQs eliminates weeks of information gathering through supply chain compliance automation capabilities that provide real-time access to validated compliance data.

Risk Reduction and Audit Readiness

Compliance automation digital transformation infrastructure transforms audit preparation from crisis response to routine operation through AI-powered compliance platform architecture.

Organizations implementing regulatory intelligence enterprise systems report:

90%+ reduction in audit preparation time through automated documentation assembly

Zero compliance findings during customer audits due to proactive gap identification

Complete traceability from raw materials to finished products through multi-tier supplier risk visibility

Proactive risk identification before regulatory deadlines through regulatory intelligence enterprise systems

Audit-ready supply chain compliance automation systems eliminate the firefighting that disrupts operations and damages customer relationships, enabling teams to focus on strategic compliance improvements rather than tactical crisis management.

Operational Efficiency Gains

While compliance automation digital transformation delivers obvious risk reduction benefits, operational improvements often exceed expectations:

Procurement Efficiency:

Automated supplier qualification and compliance validation through ERP PLM integration compliance data eliminates purchasing delays from manual verification processes, enabling procurement teams to move at market velocity.

Engineering Productivity:

Real-time material compliance feedback during design through BOM-level regulatory compliance systems prevents engineering time wasted on non-compliant approaches, accelerating time-to-market for new product introductions.

Quality Improvements:

Comprehensive supplier documentation and multi-tier supplier risk visibility correlate with reduced quality incidents and supplier performance issues, as better compliance data enables better supplier selection decisions.

Organizations measuring total cost of ownership discover AI-powered compliance platform architecture delivers ROI through operational benefits beyond regulatory compliance, fundamentally improving how enterprises make sourcing and design decisions.

Insert Image Here

Image Type: Compliance platform dashboard showing risk scores and audit readiness

Alt Text: Market readiness digital transformation dashboard with BOM-level regulatory compliance

Building Your Supply Chain Compliance Automation Roadmap

Assessment Phase for Compliance Automation Digital Transformation

Before selecting technology for compliance automation digital transformation, organizations must understand their current state:

Compliance Maturity Assessment:

Document existing compliance processes and pain points in supply chain compliance automation

Quantify manual effort and cycle times for BOM-level regulatory compliance verification

Identify regulatory frameworks and jurisdictions requiring regulatory intelligence enterprise systems

Map supplier base and documentation requirements for multi-tier supplier risk visibility

Data Readiness Evaluation:

Audit existing compliance data completeness for market readiness digital transformation

Assess supplier documentation quality and consistency across ERP PLM integration compliance data touchpoints

Identify gaps preventing market access or audit readiness through current AI-powered compliance platform architecture

Integration Requirements:

Catalog existing enterprise systems requiring compliance data for compliance automation digital transformation

Define integration priorities and phasing approach for supply chain compliance automation rollout

Establish data governance and ownership models for BOM-level regulatory compliance management

Platform Selection Criteria

Not all compliance platforms address the same challenges for compliance automation digital transformation. Evaluate based on:

Regulatory Coverage:

Does the platform monitor frameworks relevant to your markets—**PFAS, REACH, RoHS, Prop 65—**through comprehensive regulatory intelligence enterprise systems?

AI Capabilities:

Can the system actually process unstructured supplier documentation through AI-powered compliance platform architecture, or does it simply provide document storage with manual data entry for BOM-level regulatory compliance?

Multi-Tier Visibility:

Does it track compliance only for direct suppliers, or provide visibility into sub-tier material composition through true multi-tier supplier risk visibility capabilities essential for modern supply chain compliance automation?

Integration Architecture:

Does it offer flexible APIs and proven ERP PLM integration compliance data integrations with major platforms, enabling seamless compliance automation digital transformation across your existing technology stack?

Expert Support:

Does it include human-in-the-loop compliance experts who understand complex regulatory interpretations, ensuring your market readiness digital transformation efforts benefit from both AI efficiency and human expertise?

Implementation Best Practices

Successful compliance automation digital transformation rollouts follow proven patterns:

Start With Pilot:

Select a product line or business unit to prove value before enterprise-wide deployment of supply chain compliance automation capabilities, demonstrating ROI through concrete market readiness digital transformation outcomes.

Prioritize Data Quality:

Focus initial efforts on supplier data collection and validation through AI-powered compliance platform architecture before extensive system integration, establishing the foundation for BOM-level regulatory compliance across your organization.

Establish Governance:

Define roles, responsibilities, and workflows for compliance data ownership and maintenance within your regulatory intelligence enterprise systems, ensuring accountability for multi-tier supplier risk visibility data accuracy.

Measure and Communicate:

Track metrics demonstrating risk reduction, efficiency gains, and market readiness digital transformation improvements to build organizational support for compliance automation digital transformation initiatives.

Organizations treating supply chain compliance automation as foundational infrastructure rather than departmental tool achieve superior outcomes and broader organizational benefits from their compliance automation digital transformation investments.

Conclusion: Redefining Digital Transformation Priorities

Digital transformation initiatives succeed when they address fundamental business constraints before optimizing processes. For manufacturers operating in regulated industries, the fundamental constraint isn't operational efficiency—it's market readiness digital transformation and regulatory compliance.

Starting digital transformation with ERP and PLM modernization optimizes systems that cannot create value until compliance automation digital transformation foundations exist. Products manufactured efficiently but unable to clear regulatory requirements generate zero revenue regardless of operational excellence achieved through ERP PLM integration compliance data initiatives.

The most successful organizations recognize this reality and invert the traditional sequence. They establish AI-powered compliance platform architecture first, creating the intelligent foundation that enterprise systems depend on through comprehensive supply chain compliance automation. This approach delivers faster market access, reduced regulatory risk through regulatory intelligence enterprise systems, and operational benefits that exceed those from traditional digital transformation sequences.

The question facing manufacturing leaders isn't whether to modernize enterprise systems—it's whether to continue investing in operational infrastructure that assumes compliance rather than ensuring it through BOM-level regulatory compliance and multi-tier supplier risk visibility.

Organizations that continue traditional approaches will discover that years and millions of dollars into ERP and PLM implementations, they still cannot answer fundamental questions: Are our products compliant? Which suppliers pose risks? Can we prove it through comprehensive supply chain compliance automation?

Those starting with compliance automation digital transformation will already have the answers—and the competitive advantages they enable through market readiness digital transformation capabilities.

Transform Your Compliance Automation Digital Transformation

Ready to establish the foundation your digital transformation needs? Certivo's AI-powered compliance platform architecture provides the regulatory intelligence enterprise systems and market readiness digital transformation capabilities that enterprise systems depend on but cannot deliver.

Discover how leading manufacturers are accelerating market access, reducing regulatory risk, and enabling true compliance automation digital transformation through compliance-first architecture that delivers BOM-level regulatory compliance, multi-tier supplier risk visibility, and comprehensive supply chain compliance automation.

Schedule a strategic consultation to assess your compliance maturity and build your compliance automation digital transformation roadmap.

Vasanth

Vasanth is a skilled Compliance Engineer with over five years of experience specializing in global environmental regulations, including REACH, RoHS, Proposition 65, POPs, TSCA, PFAS, CMRT, EMRT, FMD, and IMDS. With a strong academic foundation in Chemical Engineering from Anna University, he brings a deep technical understanding to compliance processes across complex product lines.

Vasanth excels in analyzing Bills of Materials (BOMs), evaluating supplier declarations, and ensuring regulatory conformity through meticulous review and risk assessment. He is highly proficient in supplier engagement, adept at interpreting material disclosures, and experienced in preparing customer-ready compliance documentation tailored to diverse global standards.

Known for his attention to detail, up-to-date regulatory knowledge, and proactive communication style, Vasanth plays a critical role in maintaining product compliance and advancing sustainability goals within fast-paced, globally integrated manufacturing environments.