Lavanya

Feb 3, 2026

New Jersey has enacted one of the nation's strictest PFAS laws, establishing comprehensive sales bans on consumer products containing intentionally added forever chemicals. The Protecting Against Forever Chemicals Act (Senate Bill S1042 / Assembly Bill A1421), signed into law on January 12, 2026, creates immediate New Jersey PFAS ban compliance obligations for manufacturers, importers, and distributors selling cosmetics, carpets, fabric treatments, and food packaging into the state.

The legislation provides a two-year compliance window, with full enforcement beginning January 12, 2028. Organizations without robust regulatory change monitoring capabilities risk market exclusion, substantial civil penalties reaching $25,000 per violation, and reputational damage as enforcement intensifies. Understanding these requirements now enables strategic preparation rather than reactive scrambling as the deadline approaches.

Table of Contents

Understanding the Protecting Against Forever Chemicals Act

Key Deadlines and Compliance Timeline

Product Categories Under the Sales Ban

Cookware Labeling and Disclosure Requirements

Exemptions and Enforcement Provisions

Industries Facing Direct Compliance Impact

Business and Supply Chain Implications

Strategic Preparation Checklist for 2028

How AI Transforms PFAS Compliance Management

Understanding the Protecting Against Forever Chemicals Act

The Protecting Against Forever Chemicals Act represents New Jersey's comprehensive approach to eliminating PFAS contamination sources in household waste and the environment. The New Jersey Legislature Bill S1042/A1421 establishes the legal foundation for these restrictions under the New Jersey Department of Environmental Protection (NJDEP) framework.

PFAS, commonly known as "forever chemicals" due to their extreme environmental persistence, have drawn increasing regulatory scrutiny across federal and state jurisdictions. New Jersey's legislation positions the state among the most aggressive PFAS regulators in the nation, establishing outright sales bans rather than merely disclosure requirements or concentration limits.

The regulation targets "intentionally added" PFAS, meaning manufacturers who deliberately incorporate these substances for functional purposes such as water resistance, stain repellency, or non-stick properties face direct New Jersey PFAS ban compliance obligations. This intentionality standard affects how organizations assess product portfolios and prioritize reformulation activities through proactive compliance risk management.

Unlike federal approaches that often focus on specific PFAS compounds, New Jersey's law captures the entire PFAS class when intentionally added to covered product categories. This comprehensive scope prevents manufacturers from substituting one PFAS compound for another while continuing market access.

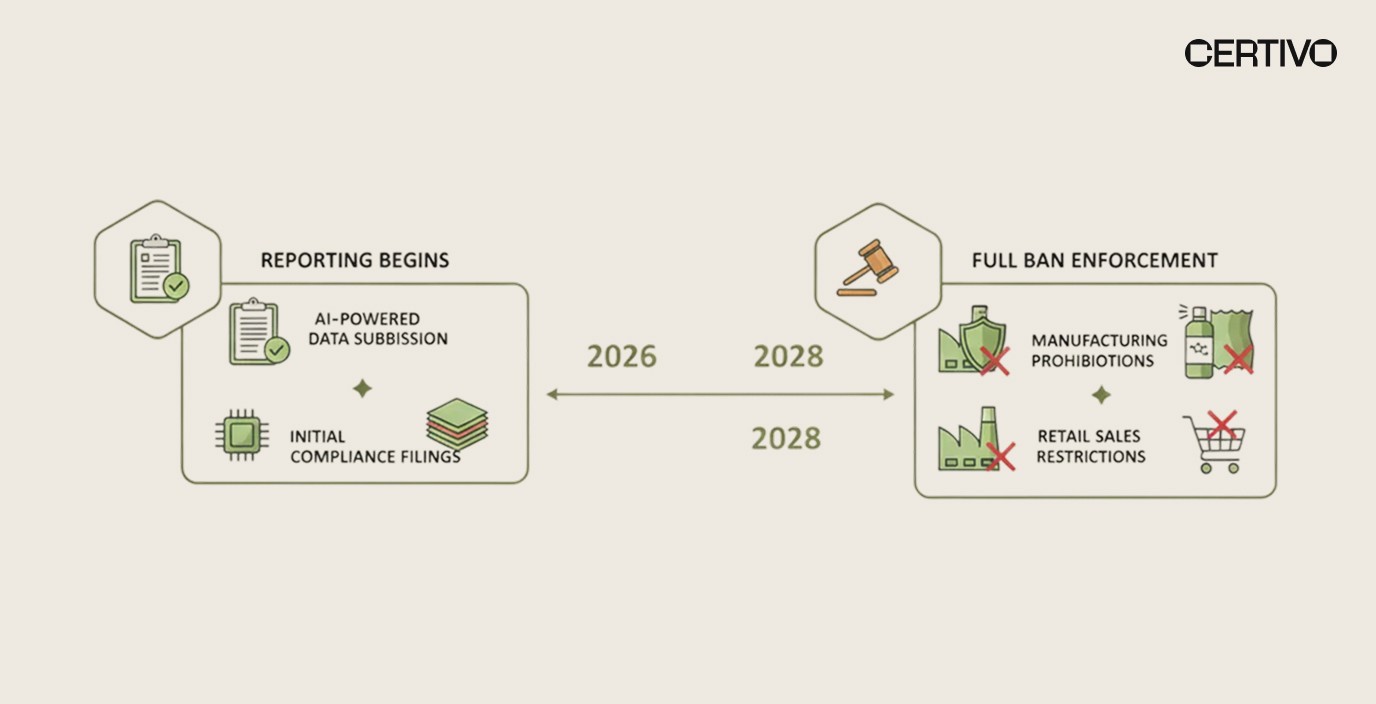

Key Deadlines and Compliance Timeline

The Protecting Against Forever Chemicals Act establishes clear milestones that organizations must track to maintain market access in New Jersey. Understanding this timeline enables strategic resource allocation and prevents last-minute compliance scrambles.

January 12, 2026: Law Enacted

This date marks the official enactment of the legislation, triggering the two-year compliance window. Organizations should have already begun product portfolio assessment, supplier engagement, and reformulation planning following this milestone.

Early 2027: NJDEP Source Reduction Program

The New Jersey Department of Environmental Protection will establish a source reduction program to help manufacturers manage and reduce PFAS in their products. This program may provide guidance, resources, and potentially technical assistance for organizations working toward New Jersey PFAS ban compliance.

January 12, 2028: Full Enforcement Begins

Starting this date, it becomes illegal to sell, offer for sale, or distribute covered products containing intentionally added PFAS in New Jersey. The prohibition applies to:

All cosmetics containing intentionally added PFAS

New carpets and rugs with PFAS content

Fabric treatments providing stain resistance or waterproofing

Non-durable food packaging made of paper, cardboard, or plant fibers

Organizations relying on manual tracking methods face overwhelming compliance burdens that AI-powered compliance platforms can systematically address before enforcement begins.

Milestone | Date | Compliance Action Required |

|---|---|---|

Law Enacted | January 12, 2026 | Begin product assessment and supplier engagement |

NJDEP Program Launch | Early 2027 | Leverage source reduction guidance and resources |

Full Enforcement | January 12, 2028 | Complete reformulation or market withdrawal |

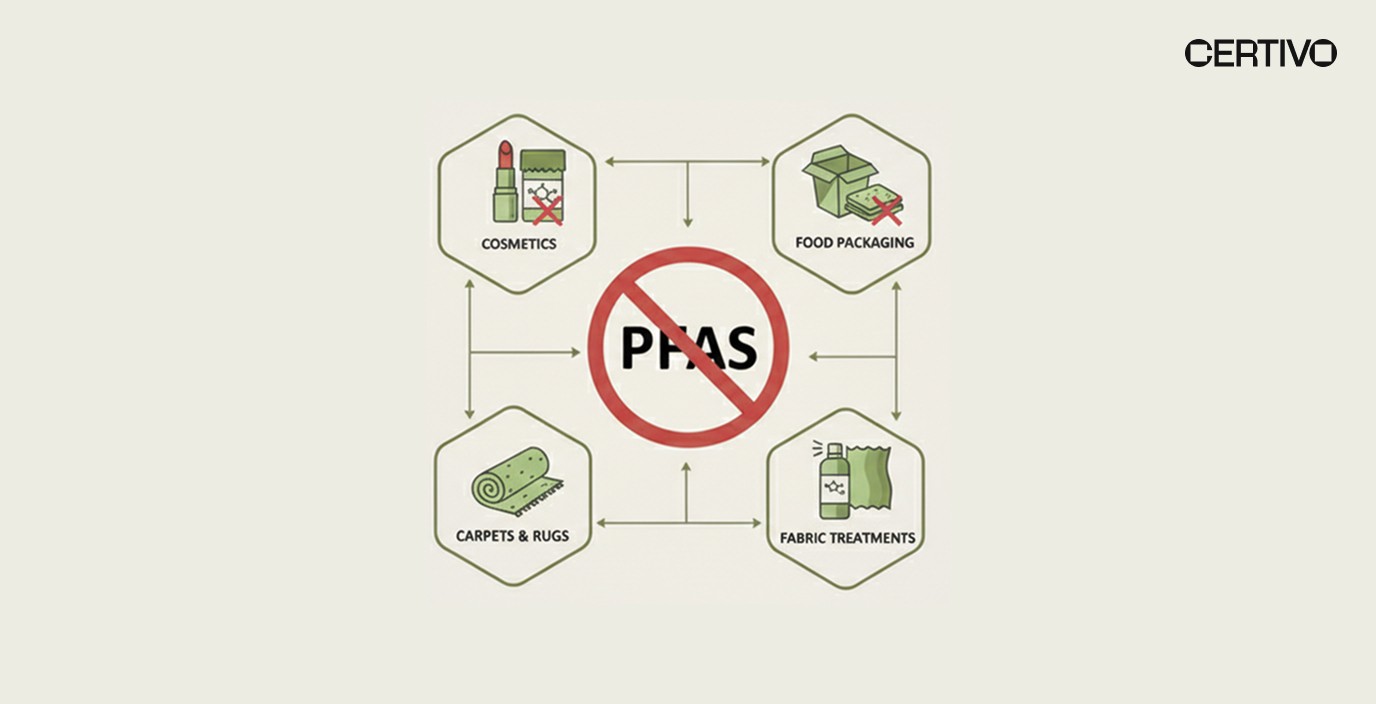

Product Categories Under the Sales Ban

The legislation establishes comprehensive sales bans across four major consumer product categories. Each category carries specific scope definitions that compliance teams must understand to assess organizational exposure accurately.

Cosmetics

The ban covers all products used for beautifying or cleaning the body, excluding soap. This broad definition encompasses:

Skincare products including moisturizers and serums

Makeup and color cosmetics

Hair care products

Personal care items

Cosmetics PFAS restrictions US represent an expanding regulatory trend, with New Jersey joining other states implementing similar prohibitions. Organizations selling into multiple state markets benefit from understanding global PFAS regulations to develop unified compliance strategies.

Carpets and Rugs

New carpets and rugs containing intentionally added PFAS face prohibition. The legislation exempts second-hand items, recognizing the impracticality of regulating existing household goods. Manufacturers and retailers of new floor coverings must ensure PFAS-free formulations or face market exclusion.

Fabric Treatments

Substances used to impart stain resistance or waterproofing properties to textiles fall under the ban. This category affects:

Aftermarket fabric protection sprays

Industrial textile treatments

Waterproofing applications for consumer use

Food Packaging

Non-durable packaging made of paper, cardboard, or plant fibers faces prohibition when containing intentionally added PFAS. Common affected products include:

Takeout containers and boxes

Paper straws and cups

Food wrappers and liners

Molded fiber packaging

Food packaging PFAS ban requirements create significant supply chain implications for restaurants, food service operations, and packaging manufacturers. Multi-tier supply chain transparency becomes essential for verifying compliance throughout distribution networks.

Cookware Labeling and Disclosure Requirements

Beyond outright sales bans, the legislation establishes parallel transparency requirements for cookware containing PFAS. These PFAS labeling requirements cookware sellers must meet by January 12, 2028, introduce compliance obligations distinct from the product category bans.

Bilingual Warning Requirements

Cookware containing PFAS must display labels including the phrase "This product contains PFAS" in both English and Spanish. This bilingual requirement ensures consumer awareness across New Jersey's diverse population and establishes clear disclosure standards.

Online Disclosure Obligations

The presence of PFAS must be clearly listed on the product's online sales page. E-commerce platforms, manufacturer websites, and digital marketplaces must update product listings to include PFAS disclosure. Organizations managing extensive online catalogs require automated compliance monitoring capabilities to ensure comprehensive disclosure across digital channels.

Non-Compliance Consequences

Cookware that fails to meet labeling standards will be prohibited from sale in New Jersey. This provision elevates labeling compliance from administrative requirement to market access prerequisite. Organizations must implement robust quality control processes ensuring every unit reaching New Jersey markets carries compliant labeling.

Cookware Requirement | Specification | Deadline |

|---|---|---|

Physical Label | "This product contains PFAS" in English and Spanish | January 12, 2028 |

Online Disclosure | PFAS presence listed on product sales page | January 12, 2028 |

Non-Compliance Penalty | Product prohibited from sale | Immediate upon enforcement |

Exemptions and Enforcement Provisions

The legislation includes specific exemptions and enforcement mechanisms that compliance teams must understand to assess organizational exposure and prepare appropriate responses.

Electronic Components Exemption

PFAS used in internal or electronic parts of products are exempt from the prohibition. This exemption recognizes the technical necessity of certain PFAS applications in electronics while maintaining focus on consumer exposure pathways. Organizations must carefully document which PFAS uses qualify for this exemption through continuous audit-ready documentation practices.

Trace Amounts Exemption

"Technically unavoidable trace residues" from manufacturing processes or impurities are generally not considered violations. This exemption acknowledges that complete PFAS elimination may be technically impossible in some manufacturing contexts. However, organizations cannot rely on this exemption for intentionally added PFAS regardless of concentration levels.

Civil Administrative Penalties

Violations trigger civil administrative penalties ranging from $1,000 to $25,000 per violation. Critically, each non-compliant product or sale can be treated as a separate offense. This multiplier effect means organizations with widespread non-compliance face potentially catastrophic financial exposure.

Consider the penalty mathematics: A retailer with 1,000 non-compliant units faces potential penalties between $1 million and $25 million. This enforcement structure creates compelling economic incentive for New Jersey PFAS ban compliance investment.

Industries Facing Direct Compliance Impact

The Protecting Against Forever Chemicals Act creates varying compliance obligations across industries based on product portfolios, supply chain structures, and New Jersey market exposure.

Cosmetics and Personal Care

Cosmetics manufacturers face comprehensive New Jersey PFAS ban compliance requirements across virtually all product categories. The exclusion of soap from the definition provides narrow relief, but most beauty and personal care products fall within scope.

Organizations should assess formulations for PFAS-containing ingredients including:

Long-wear and waterproof cosmetics

Conditioning agents in hair care

Smoothing agents in skincare

Slip agents in color cosmetics

Global cosmetics industry regulatory shifts continue reshaping formulation requirements. Organizations reformulating for New Jersey compliance gain competitive advantages as similar restrictions emerge in other jurisdictions.

Food Service and Packaging

Food packaging manufacturers and food service operators face significant supply chain reconfiguration requirements. PFAS have been commonly used in food packaging for grease resistance, moisture barriers, and structural integrity. Replacing these functional properties requires material science expertise and supplier qualification activities.

Streamlined supplier documentation becomes critical for food service operators who must verify that packaging suppliers provide PFAS-free alternatives meeting performance requirements.

Textile and Flooring

Carpet manufacturers and fabric treatment suppliers face complete market exclusion for PFAS-containing products. The stain resistance and waterproofing properties that PFAS provide have been selling points for decades. Transitioning to alternative technologies while maintaining performance claims requires careful product development and marketing adjustment.

Cookware and Housewares

Cookware manufacturers face disclosure requirements rather than outright bans, but the labeling obligations still demand systematic compliance programs. Organizations must implement bilingual labeling, update online product information, and establish processes ensuring consistent compliance across production runs and sales channels.

Business and Supply Chain Implications

New Jersey PFAS ban compliance creates business consequences extending beyond direct regulatory obligations. Organizations must understand these implications to secure executive support for compliance investments and coordinate effectively across functional areas.

Market Access and Commercial Continuity

Products failing to meet requirements face complete market exclusion from New Jersey. For manufacturers with significant New Jersey revenue exposure, non-compliance threatens commercial viability rather than merely creating regulatory friction. The state's population and economic significance make market withdrawal an unattractive option for most national brands.

Supply Chain Reconfiguration

Global supply chains may require significant reconfiguration to source PFAS-free materials and formulations. Procurement and supply chain leaders should evaluate supplier capabilities now, identifying which partners can support compliance and which require replacement.

Key supply chain activities include:

Surveying current suppliers regarding PFAS content

Qualifying alternative suppliers with PFAS-free offerings

Establishing incoming material testing protocols

Implementing supplier compliance certification requirements

Reformulation Investment

Product reformulation to eliminate intentionally added PFAS requires R&D investment, testing, and potential manufacturing process modifications. Organizations should budget appropriately for:

Alternative material evaluation

Performance testing and validation

Manufacturing process adjustments

Regulatory documentation updates

Competitive Positioning

Early compliance achievement creates competitive advantages as the January 2028 deadline approaches. Organizations demonstrating New Jersey PFAS ban compliance can assure customers of continued supply while competitors struggle with reformulation delays. Responding faster to customer RFQs requires compliance documentation systems capable of producing current certifications efficiently.

Strategic Preparation Checklist for 2028

Organizations should implement systematic preparation activities to achieve and maintain New Jersey PFAS ban compliance before the enforcement deadline.

Product Portfolio Assessment

Identify all products sold or distributed in New Jersey

Screen formulations for intentionally added PFAS

Categorize products by ban applicability versus labeling requirements

Prioritize products by revenue exposure and reformulation complexity

Supplier Engagement and Qualification

Survey suppliers regarding PFAS content in materials and components

Collect material declarations and compliance certifications

Qualify alternative suppliers where current sources cannot comply

Establish ongoing monitoring for supplier compliance status

Effective supplier collaboration enables early identification of supply chain gaps requiring remediation.

Reformulation and Testing

Develop PFAS-free formulations for affected products

Validate performance characteristics meet market requirements

Document reformulation processes for regulatory inquiries

Establish quality control protocols ensuring consistent compliance

Labeling and Disclosure Systems

Design compliant bilingual labels for cookware products

Update online product listings with PFAS disclosure

Implement quality control checkpoints for labeling accuracy

Establish e-commerce platform update procedures

Documentation and Audit Readiness

Implement compliance documentation management systems

Create audit-ready record retention protocols

Develop enforcement response procedures

Establish exemption documentation for electronic components

Building future-ready compliance infrastructure positions organizations for ongoing regulatory evolution beyond New Jersey requirements.

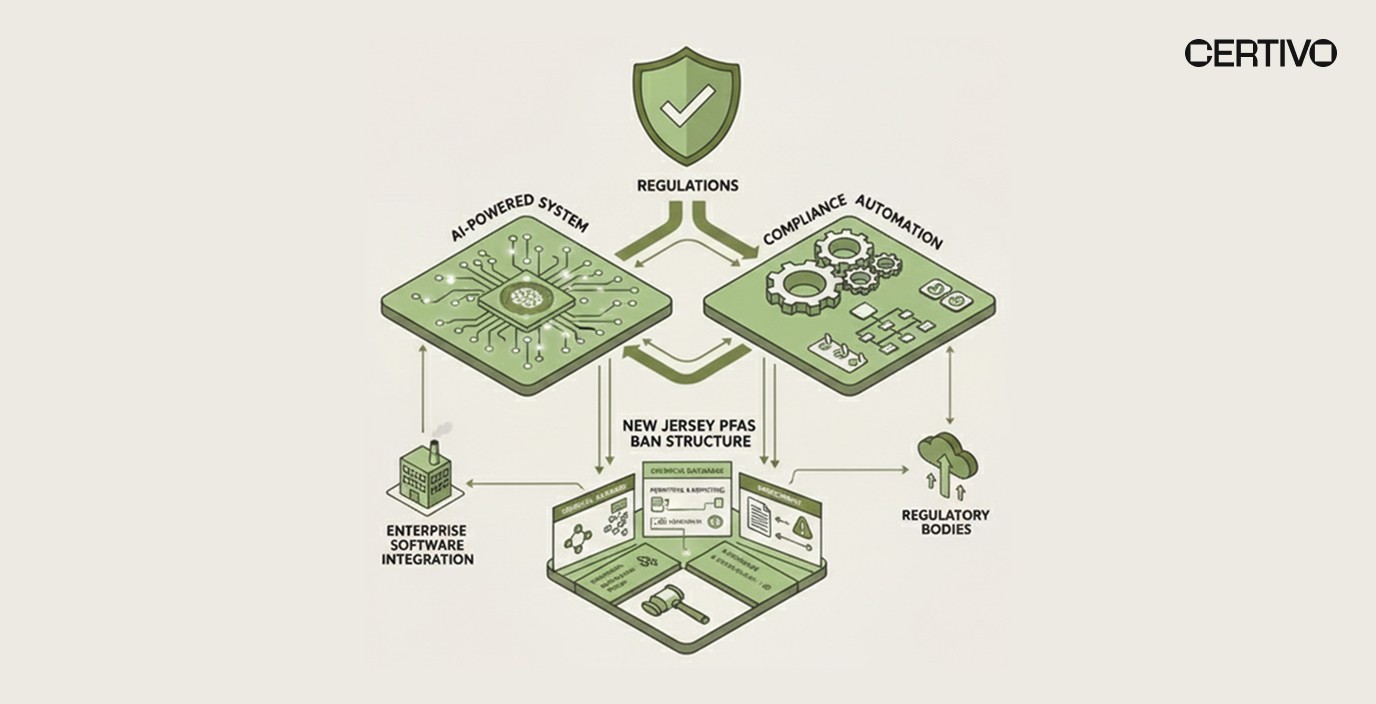

How AI Transforms PFAS Compliance Management

Manual compliance approaches cannot scale to address the complexity of New Jersey PFAS ban compliance across extensive product portfolios and multi-tier supply chains. AI compliance software PFAS capabilities fundamentally transform organizational capacity for regulatory monitoring, supplier management, and documentation maintenance.

Intelligent Regulatory Monitoring

PFAS regulatory landscapes evolve continuously across federal, state, and international jurisdictions. New Jersey's restrictions represent one element of broader PFAS regulation sweeping across the United States. Automated regulatory monitoring chemicals capabilities track developments across relevant markets, alerting compliance teams to changes requiring response.

Understanding why people-only compliance cannot scale helps executives appreciate the strategic value of AI-powered monitoring operating continuously across regulatory domains.

Automated Supplier Data Collection

Supply chain compliance requires systematic data collection from potentially hundreds of suppliers across multiple tiers. Certivo's platform incorporates CORA, an intelligent assistant that automates supplier follow-ups and data completion workflows. Rather than manual email chasing, CORA systematically engages suppliers to collect PFAS declarations, reducing administrative burden while improving data completeness.

Product Portfolio Screening

Product portfolios spanning thousands of SKUs require systematic screening against PFAS content. AI platforms enable automated screening that identifies products requiring reformulation or labeling within hours rather than weeks of manual review. This capability proves particularly valuable when regulations like New Jersey's affect multiple product categories simultaneously.

Audit-Ready Documentation

Compliance documentation must demonstrate current practices aligned with forever chemicals regulation compliance requirements. AI platforms maintain audit-ready documentation that evolves as regulations change. Staying audit-ready across frameworks becomes systematic compliance practice rather than episodic scramble.

Regulatory Horizon Scanning

Beyond immediate New Jersey requirements, organizations benefit from regulatory horizon scanning intelligence that identifies emerging PFAS restrictions across other jurisdictions. This forward-looking capability enables proactive reformulation decisions that satisfy multiple regulatory requirements simultaneously, reducing overall compliance costs.

Conclusion: Strategic Imperatives for New Jersey Market Access

The Protecting Against Forever Chemicals Act establishes one of the nation's strictest PFAS regulatory frameworks, creating comprehensive sales bans and labeling requirements that affect manufacturers across cosmetics, food packaging, textiles, and cookware sectors. The January 12, 2028 enforcement deadline provides limited time for organizations to reformulate products, reconfigure supply chains, and implement compliant labeling systems.

The business consequences of non-compliance extend beyond regulatory penalties to include complete New Jersey market exclusion, with civil penalties reaching $25,000 per violation creating potentially catastrophic financial exposure for organizations with widespread non-compliance. Organizations recognizing these stakes are investing in AI compliance software PFAS capabilities that automate regulatory monitoring, supplier data collection, and documentation management.

The two-year compliance window demands immediate action. Organizations should begin product portfolio assessment, supplier engagement, and reformulation planning now to ensure readiness before enforcement begins. Those that delay face compressed timelines, elevated costs, and increased risk of missing the deadline.

Executive leadership must recognize that New Jersey PFAS ban compliance represents a leading indicator of broader regulatory trends affecting PFAS consumer product restrictions nationwide. Building robust compliance infrastructure today positions organizations to address not only New Jersey requirements but the continuing evolution of forever chemicals regulation compliance across federal and state jurisdictions.

Explore how Certivo can support your PFAS compliance readiness and develop AI-powered strategies ensuring continued market access while reducing compliance operational burden.

Lavanya

Lavanya is an accomplished Product Compliance Engineer with over four years of expertise in global environmental and regulatory frameworks, including REACH, RoHS, Proposition 65, POPs, TSCA, PFAS, CMRT, FMD, and IMDS. A graduate in Chemical Engineering from the KLE Institute, she combines strong technical knowledge with practical compliance management skills across diverse and complex product portfolios.

She has extensive experience in product compliance engineering, ensuring that materials, components, and finished goods consistently meet evolving international regulatory requirements. Her expertise spans BOM analysis, material risk assessments, supplier declaration management, and test report validation to guarantee conformity. Lavanya also plays a key role in design-for-compliance initiatives, guiding engineering teams on regulatory considerations early in the product lifecycle to reduce risks and streamline market access.

Her contributions further extend to compliance documentation, certification readiness, and preparation of customer deliverables, ensuring transparency and accuracy for global stakeholders. She is adept at leveraging compliance tools and databases to efficiently track regulatory changes and implement proactive risk mitigation strategies.

Recognized for her attention to detail, regulatory foresight, and collaborative approach, Lavanya contributes significantly to maintaining product compliance, safeguarding brand integrity, and advancing sustainability goals within dynamic, globally integrated manufacturing environments.